Unlock the Power of Digital Root Cause Analysis in Factories

Discover how a digital identification, investigation and reporting of Root Cause Analyses can improve your continuous improvement efforts.

Root Cause Analysis (RCA) is a critical part of a plant’s continuous improvement efforts. As a systematic approach, it empowers users to find and eliminate the root cause of an issue, event or deviation, ensuring it doesn’t happen again. For these reasons, RCAs can unlock a number of plant-wide benefits, including reduced downtime and costs.

Connected worker platforms take these benefits a step further, storing RCA information as knowledge articles that are accessible anytime, anywhere. They also enable you to streamline and manage RCA tasks, trigger maintenance requests, employ countermeasures, and much more.

Determining a deviation’s reason and remedy depends on many factors. Let’s explore the ways connected worker platforms like 4Industry support the identification, investigation, and reporting of Root Cause Analyses, taking your continuous improvement efforts to the next level.

What is a Root Cause Analysis?

An RCA is a problem-solving method to identify the root cause of a problem or fault. In the context of a connected worker platform, it is a digital tool that enables users to collaborate remotely with colleagues, vendors, and other stakeholders to find the root cause of a deviation or equipment breakdown. You can perform an RCA using multiple processes like the 5xWHY methodology, which is based on lean manufacturing principles.

Why would I perform a Root Cause Analysis?

Ultimately, the decision to create and perform an RCA comes down to cost. If a deviation recurs, for example, causing extended periods of downtime and driving up maintenance costs, then it would make sense to eliminate the underlying cause so that it doesn’t happen anymore. RCAs are also a common procedure after a personnel injury or other safety incident.

How do you create and perform an RCA?

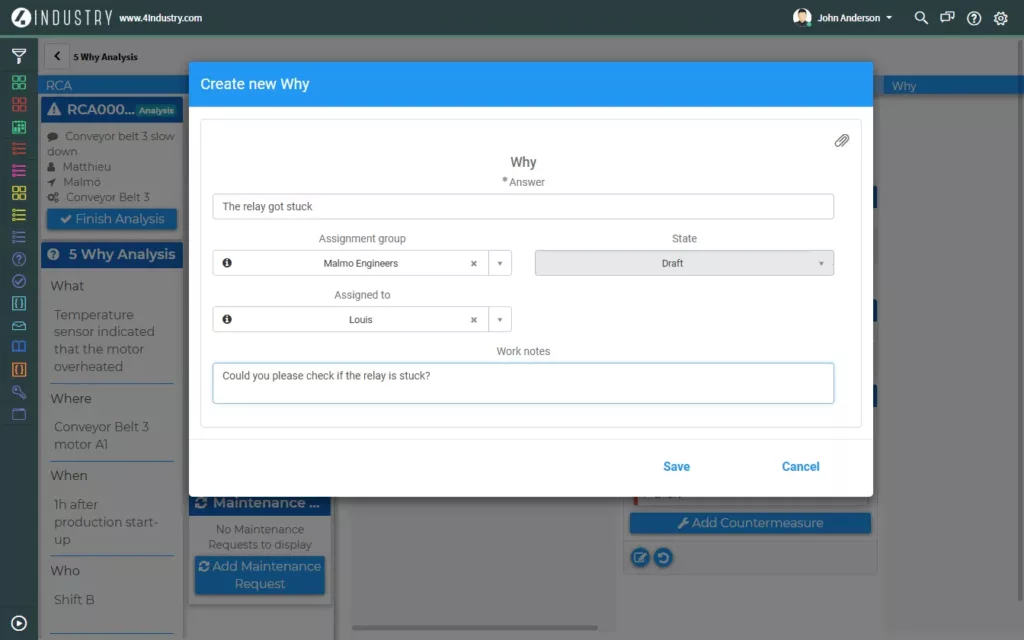

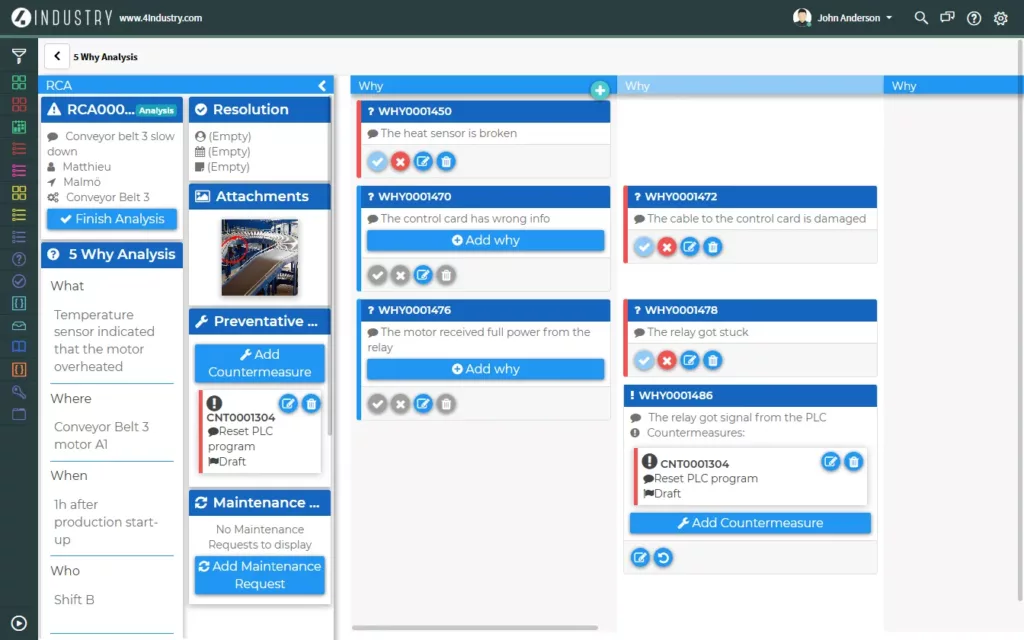

4Industry lets you create an Root Cause Analysis in several different ways. For example, you can visit a deviation record and click “New RCA,” creating an analysis linked to it. From there, you can add any information relating to the analysis, including images and other helpful attachments. Once you create the RCA, you can apply the 5xWHY technique directly within the application. This technique is one of the most effective tools in the RCA arsenal and consists of asking “why” at least five times regarding something that happened. Whenever you create a new WHY, a pop-up will appear, prompting you to fill in the required information. You can then select whether the WHY was a cause that impacted the deviation; if it has, you can create additional WHYs, bringing you closer to the root cause of the issue.

Once you identify a WHY as the root cause, the platform automatically stores the answer to the RCA record. You can also input additional information about the issue, including the WHAT, WHERE, WHEN, WHO and WHY, as well as any countermeasures. You can even request maintenance directly from the analysis application.

What happens to the information once an RCA is closed?

The beauty of 4Industry is that an RCA record is immediately accessible by anyone, anywhere—transcending shifts, supervisors, and even plant locations. Without such a digital system in place, it’s easy to misplace or forget about any knowledge acquired during the RCA process: pen-and-paper notes are thrown out, and spreadsheets become lost on the computer’s hard drive, driving up time and frustration should you need to access the file again.

4Industry, on the other hand, adds all RCA records to its intuitive, interactive and searchable knowledge base. It also lets you create additional knowledge articles using RCA workflows. Thanks to these features, the next time a deviation occurs that resembles a closed Root Cause Analysis case, you can easily access relevant knowledge articles for assistance, gaining a headstart in the problem-solving process.

Does 4Industry provide any additional RCA features?

Yes. In addition to committing all RCA information to its comprehensive knowledge base, 4Industry lets you define the conditions under which an RCA can be automatically generated. For example, you can trigger an analysis if a production line stops for more than two hours. Then, the further your plant grows in its maturity, the tighter those triggers can become—for example, every 15 minutes versus two hours.

How should manufacturers begin to implement Root Cause Analyses?

It’s okay to start small—especially if you’ve never implemented a Root Cause Analysis before. You can set goals like performing one RCA every month or week, or investing in RCA-related training for your employees. Then, over time, you can begin to increase the frequency of your RCAs or take on more difficult analyses that require more complex WHYs.

Related Articles

Digitize your inspections, audits and checklists

4Industry targets Nordic market via strategic partnership with Advania