Food & Beverage industry

Digitize your TPM processes with our mobile-enabled platform, increasing worker productivity and OEE.

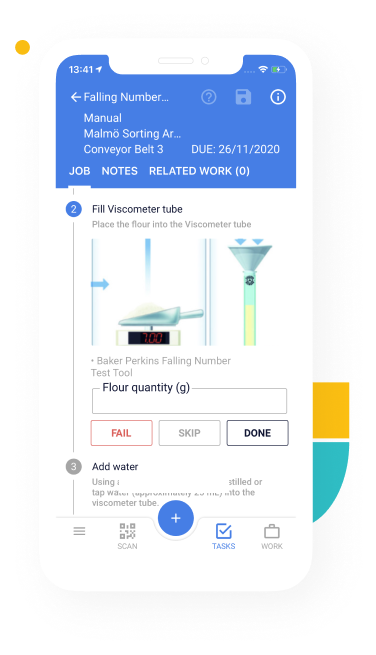

Boost productivity with a superb operator experience

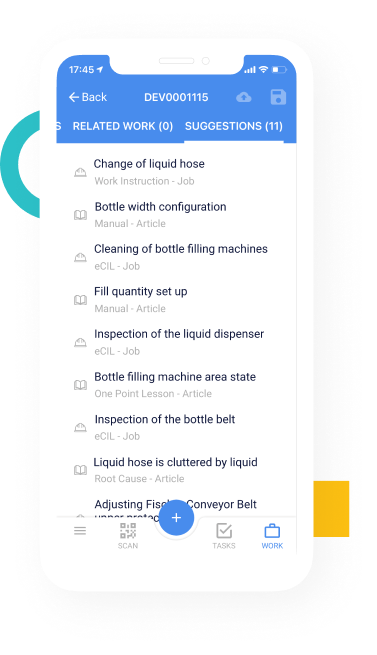

With the Food & Beverage industry being the largest industrial segment and employer, investing in productivity (Overall Labor Effectiveness) is key to maintain your competitive edge. Since operators spend most of their time on the factory floor or on the go, the interest in mobile manufacturing apps has increased. However, we also see that way too many seperate solutions are implemented. This leads to confusion on the operator’s side, not knowing when to use which app. Our mobile-enabled connected worker platform solves this problem by providing an intuitive and unified user experience. All operator actions, insights, and knowledge are combined in a single manufacturing app that is extremely user-friendly and tailored to the shop floor, allowing you to increase operator productivity.

Digital knowledge fuels your workforce

The phrase “Knowledge is Power” is a universal truth. But this only holds true when the right information is available at the right time and place. What we often see at Food & Beverage plants is that knowledge is locked in the minds of a few critical operators. This poses a significant risk when these operators are out sick, cannot access a site (e.g. due to COVID regulations) or retire. Knowledge in the minds of people also doesn’t scale geographically. 4Industry supports manufacturers to digitize their knowledge capturing and consummation processes. This leads to a more flexible workforce, where the wheel is invented only once. Furthermore, digital knowledge allows for learning on the job—reducing classroom training needs and the time needed to upscale on operators.

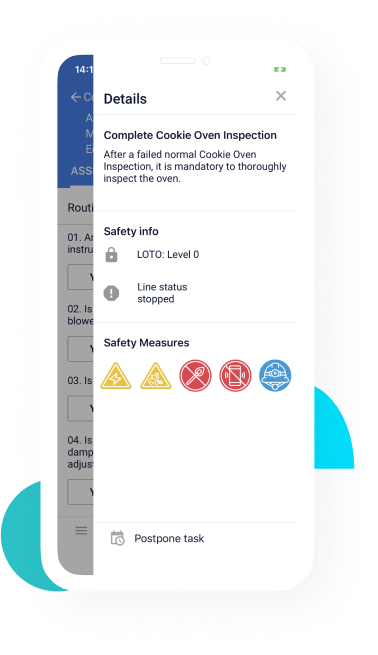

Safety first!

As we all know: on a factory floor, Occupational Health and Safety (OHS) hazards are just around the corner. Mitigating accident risks brings along many benefits, like reduced staff turnover, higher productivity and reduced insurance premiums. 4Industry offers a full-fledged EHS module to ensure compliance to OHS standards like ISO 45001. We’ve weaved OHS/EHS processes into every shop floor activity and digital work instructions. This ensures Occupational Health and Safety is not an afterthought, but an integral part of manufacturing operations. Other benefits are easier tracking, auditing and OHS risk reduction.

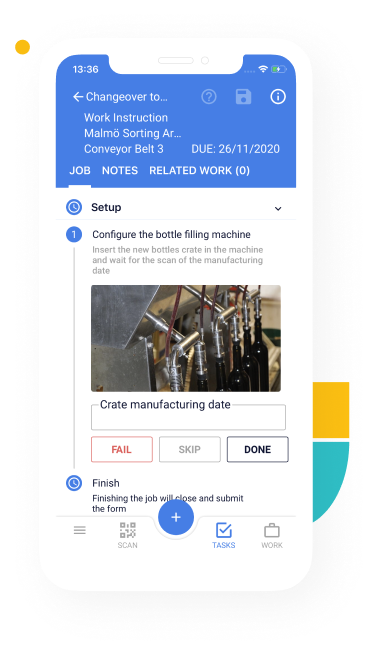

Minimize waste associated to frequent line changes

Customer preferences are rapidly changing. In the Food & Beverage industry, the number of product variations are increasing as well. This leads to frequent line changes. Adjusting the equipment of your production line needs to be strictly controlled to avoid loss of yield. 4Industry provides the digital means to successfully perform line changes:

- Store line configurations at the click of a button

- Define SMED to reduce line change time and ensure procedures are followed

- Associate deviations to batches to perform root cause analysis on specific line configurations

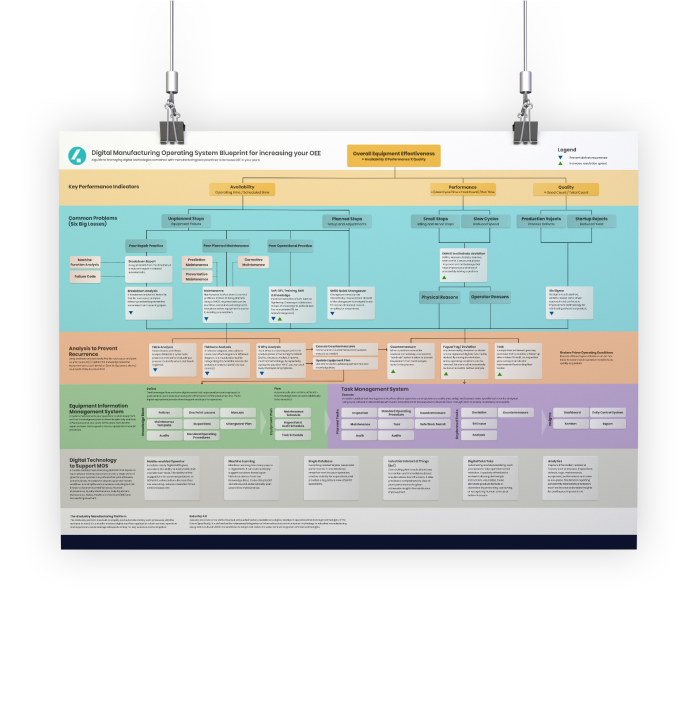

Digital TPM to achieve a world-class OEE

4Industry is a connected worker platform that helps plants realize world-class OEE levels (>85%). It digitizes TPM for the Food & Beverage industry and consolidates all continuous improvement workflows in a single platform:

- Digital work instructions & SOPs — Improve operator productivity with digital instructions

- Digital knowledge — Shorten resolution times by sharing knowledge across the globe

- Digital audits — Enhance compliance by embedding compliance checks in tasks

Easily comply to food safety regulations

In 4Industry, food/beverage safety policies are embedded in operational procedures. That way, you can effortlessly demonstrate compliance. Easily plan audits and use the findings as input for continuous improvement workflows, allowing you to connect shop floor and compliance processes and vice versa.

Digital TPM for the Food & Beverage industry

TPM has been around since 1971. Way back then, many Food & Beverage companies adopted the TPM method to improve OEE. But it’s like time has stood still. Many factories still use antiquated tools to support their TPM processes—from pen and paper, Excel, SharePoint, local on-premise solutions to point solutions. This leads to scattered and inaccessible data and leaves operators confused on when to use what. 4Industry digitizes all TPM Food & Beverage processes and brings them together on a single platform. It captures Continuous Improvement data in a central database, accessible via a unified (mobile) interface, providing a consolidated overview on global manufacturing operations.

Make your IIoT initiatives a success

Technologies like IIoT hold the promise of proactively identifying breakdowns. However, many IIoT initiatives fail because they are decoupled from what’s happening on the shop floor. Here’s how 4Industry connects your operators to your IIoT technology:

- EIMS — Correlates IIoT data to equipment, understands context triggers and auto-creates related response tasks

- Intuitive user interface – Allows teams to define event triggers for the equipment in their work area(s)

- Global deviation database — Enables you to identify the most valuable IIoT use cases

Trusted by our customers and partners