How to Reduce Non-conformances in Manufacturing

Learn everything there is to know about non-conformances and discover how digital tools eliminate them from your shop floor.

In manufacturing, a non-conformance is a deviation from standard operating procedures (SOPs) or a quality defect in the end-product. Non-conformances are a major pain point to manufacturers. Their consequences can be costly, damaging to a company and its reputation, and detrimental to production output.

In this article, you’ll learn everything there is to know about non-conformances.

We’ll also explain how digital technology can help manufacturers prevent and react to non-conformances, using 4Industry’s new non-conformance module as an example.

What is a non-conformance in manufacturing?

In manufacturing, non-conformances occur when a process or end-product deviates from the requirements specified by a regulatory entity, device master record, or internal company guidelines.

They can be found in two areas: quality defects in the end-product itself and deviations from standard operating procedures (SOPs) in a shop floor process.

Non-conformances can put enormous strain on manufacturers, causing reputation damage, high costs due to recalls and amendments, and, consequently, a slowing down of production.

A recent example of this is the Dutch company Philips, which had to recall 17 million sleep masks and 5.5 million machines due to a product defect. The recall led to a significant financial strain for the company and considerable frustration among its investors.

The two types of non-conformances in manufacturing

Non-conformances come in two forms in manufacturing; there are major and minor ones.

Major non-conformances have great impact on product quality. They often result from a combination of mistakes that are difficult to spot. It’s therefore easy for them to slip through the quality assurance process and impact the consumers.

Here are a few examples of major non-conformances:

- Major neglect of Quality Management standards like ISO9001

- Repeated unauthorized changes to SOPs

- Failure to implement corrective and preventive actions (CAPAs)

- Fault with a Quality Management System

Minor non-conformances occur infrequently and have little impact on the consumer. They are often unique occurrences that are easy to spot. Examples are single cases of missing documentation, unauthorized changes, or the use of wrongly adjusted equipment.

How to prevent non-conformances in manufacturing

There are two approaches to reducing non-conformities in manufacturing: a preventive approach and a reactive approach.

Let’s start off by exploring how manufacturers can prevent non-conformances from occurring.

The most significant cause of non-conformances on the shop floor is human error. In other words, frontline personnel diverting from directions.

That is not necessarily their own fault; often, the root cause is that operators have inaccurate, unclear, or outdated standard operating procedures (SOPs).

The easiest way to combat this, naturally, is to provide operators with accurate SOPs, and digital tools provide the perfect solution for this.

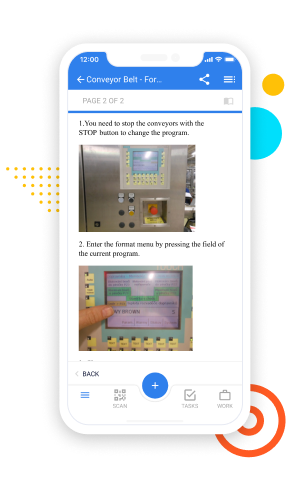

Mobile-enabled SOPs and production start-up checklists ensure that your operators always have the correct information to perform a task in the palm of their hand.

Documents are media-rich as they can be embedded with images and videos that significantly improve the clarity of instructions. When an operator has a picture of the end-product, material, or part in front of him, the chance of a mistake being made is much smaller.

Mandatory digital checklists ensure that an operator has followed every necessary step in a process, that all machines are calibrated correctly, and that the correct ingredients or raw materials are being used.

Furthermore, digitalized SOPs can be instantly updated factory-wide, eliminating the risk of frontline personnel using outdated instructions.

How manufacturers can deal with non-conformities

The following five steps form a guideline on how manufacturers can reactively deal with non-conformances. Let’s walk through them one by one, and then explore how digital technology makes them easier to implement.

- Registration

Non-conformances can be identified in different ways. First, customer feedback and external inspections can trigger the detection of a non-conformance. Internally, frontline workers and Quality personnel can spot non-conformances through testing, audits, and simple observation.

When a non-conformance is detected on the shop floor, operators should file a non-conformance report that describes and gives data on the possible non-conformance (PNC).

- Containment

Quality teams should be alerted as soon as possible so that any preliminary containment measures can be taken, like halting the shipping of the possibly defective products.

If it turns out a non-conformance has occurred, an immediate corrective action should be implemented to eliminate the surface-level cause of the non-conformance. If possible, the defective products can at this point be reworked to get them to their required quality level.

- Analysis

This step is crucial to prevent a non-conformance from occurring in the future. Through the use of assessments and root cause analysis techniques, Quality and frontline personnel should pinpoint the ultimate cause of the non-conformance.

- Correction

Once the root cause of the non-conformance has been established, a long-term corrective action can be planned and implemented.

- Monitoring

Although we’re nearly there, this step is just important as the others. Just because a well-researched corrective action has been implemented, that doesn’t mean that the non-conformance should be forgotten. It should be closely monitored that it doesn’t recur in a similar situation that caused the original non-conformance. If it doesn’t, the non-conformance report can be closed.

How digital tools reduce non-conformances

Although reducing non-conformances is a great priority for manufacturers, the largely analog checks and balances to battle them come with quite a number of challenges.

Due to unstructured communication methods and a lack of shared technology, it’s also easy for operators and Quality teams to work in silos, not knowing what the other is doing about a non-conformance.

A Connected Worker Platform like 4Industry makes it significantly easier to integrate the above 5 steps into day-to-day shop floor operations and guarantee that they are adhered to by frontline personnel.

- Registration

A common point of frustration on the shop floor is that operators do not know how to contact their Quality colleagues when they spot a potential non-conformance. Next to being frustrating, this inability to quickly respond to a PNC can also have tremendous negative consequences on production itself.

Using a mobile-enabled Connected Worker Platform, your operators have everything necessary to file a PNC report right on their handheld device. By opening up a digital non-conformance report in 4Industry, operators can fill in all necessary information about the non-conformance and immediately send it to the appropriate personnel.

The great thing about this is that all NC data is stored securely in a centralized database. This isn’t solely accessible to a local site’s employees; global Quality teams can also access it and use its results to implement improvements in other factories.

- Containment

Moving on to this step, we encounter the problem of operators and Quality teams working in silos. On the one hand, operators often do not know what to do to contain a PNC; on the other, Quality teams have no way of ensuring that their prescribed corrective actions are implemented on the shop floor.

To fix this split in communication, a Connected Worker Platform again comes in handy. After having analyzed the initial non-conformance report, Quality teams can prescribe a corrective action and auto-assign it through the platform. Operators will accordingly receive a task notification on their mobile devices, of which Quality teams can track the completion. Furthermore, the task can have relevant knowledge articles attached to it, so that operators know exactly what to do to effectively contain the non-conformance.

- Analysis

To deepen the analysis of the problem, Quality teams can digitally assign operators assessments and audits, the results of which can be immediately viewed upon completion.

Furthermore, the teams can collaborate on a root cause analysis and use digital versions of RCA tools like the 5 Whys. RCA results can be stored indefinitely for future use. This way, other plants, when they run into a similar non-conformance, immediately have the right solution to solve their problem.

- Correction

Similar to the preliminary corrective actions in the containment phase, Quality teams can assign operators proper long-term CAPAs remotely once a root cause has been detected.

- Monitoring

Again in this last phase, the problem of communication pops up. Before, Quality teams had no way of checking if their CAPAs were implemented, and further difficulty on getting data on when they were implemented, by who, etc.

With a Connected Worker Platform, Quality teams have a complete audit trail of performed activities, they can therefore track if a CAPA has been completed, which operator(s) completed it, when they completed it, etc. They can furthermore monitor if a CAPA is effective when a similar situation occurs that caused the original non-conformance.

Other ways to reduce non-conformances

Apart from the above steps, which illustrate how shop floor personnel should react to a possible non-conformance, here are some ways in which a Connected Worker Platform like 4Industry prevents the occurrence of non-conformances.

Approval flows

4Industry has a module dedicated to digitalizing SOPs.

This comes with automated approval flows that are triggered whenever someone wants to make a change to an SOP.

It’s therefore impossible that any crucial document is changed without the appropriate authorization.

Actionable IoT triggers

Through 4Industry’s Task Management features, operators receive automatic notifications whenever an IoT sensor indicates that a threshold has been exceeded.

This enables your operators to react immediately when a machine deviates from its normal settings, ensuring that a non-conformance is spotted and taken care of quickly.

Related Articles

How to ensure social distancing in manufacturing

4 Ways digital helps manufacturing during COVID-19