Get your OEE calculation just right with a DMOS

Getting your OEE calculation right can be really challenging. But those days are over with a DMOS that interconnects your SCADA and MES!

Getting your OEE calculation right can be really challenging. You need to register every loss in time or material, no matter small or big, including its exact duration and loss type. Especially in plants where systems like SCADA, MES and DMOS are disconnected, operators need to fill the gap by registering the same information multiple times, with an inherent risk of errors and lack of precision.

A single and streamlined workflow results in more accurate data, making your OEE calculations more precise. A simpler workflow also increases worker happiness, as they don’t have to spend time performing repetitive tasks and can focus on more value-adding tasks like Autonomous Maintenance.

Before we dive into how most plants currently yield their data for OEE calculation, make sure you’ve got the role and purpose of a SCADA, MES and DMOS clear.

OK, so, let’s look at the deviation workflow that is commonly used in plants to capture OEE calculation data when a MES, SCADA and DMOS aren’t connected.

It’s Monday morning, 9 AM, and the operator starts his shift. After a routine check on a machine, he goes back to the control room and discovers a SCADA notification for the packaging machine. Before checking it, he mentally registers the start time of the breakdown. He could register the breakdown in the MES, but he chooses to do it later in order to speed up the time to repair.

He inspects the machine and finds out that the glue roller is worn. After registering the deviation including error code, the knowledge database suggests replacing the glue roller. The operator replaces the roller. Once back in the control room, the operator fills a paper form with the approximate start and stop time of the breakdown, the equipment and the failure mode. All forms are collected at the end of the day and then registered in the MES for OEE calculation.

Did you notice the inefficiency in this example? And the double work?

As SCADA, MES and DMOS aren’t connected, the operator needs to register the same information multiple times. Apart from a waste of the operator’s time, it widens the gap between the moment SCADA is aware of a problem and the actual repair work. OEE calculation accuracy is also impacted, as the process highly depends on the accuracy of a paper form, which might even get lost along the way. As a result, not all breakdowns might be captured, especially short ones.

In the long term, this will affect data accuracy in your systems because each record is updated separately at a different point in time, with different information coming from different people. KPIs like OEE could also deviate as one system contradicts the other and reconciliation can prove to be difficult. On top of all that, working like this makes it hard to understand what actions have been taken in order to fix the problem.

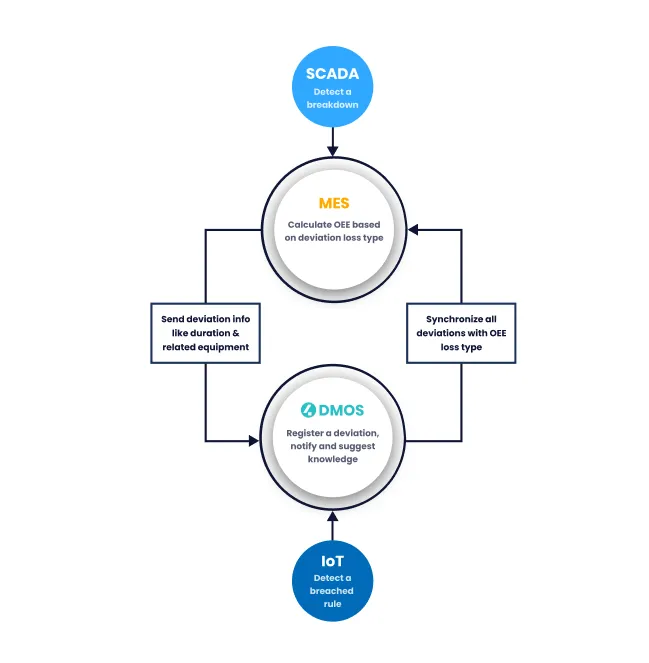

Now, let’s see what happens when your systems are interconnected by a DMOS.

Connecting the dots with a DMOS

It’s Monday morning, 9 AM, and the operator starts his shift equipped with a smartphone. During a routine check on a machine, he receives a notification from the mobile DMOS app (like 4Industry). The SCADA detected an error on the packaging machine. The operator receives the notification because he was working in that area.

When he arrives at the packaging machine, the operator inputs the error code in the DMOS. Based on this, the glue roller replacement SOP pops up. He follows the work instructions and restarts the machine. Back in the control room, he decides to close the deviation. All records created in the MES and DMOS are automatically updated, so no further action is required from the operator.

A must for correct OEE calculation

So, what did we learn from above examples? Interconnection between SCADA, MES and DMOS is super important for correct OEE calculation. Because both systems need to be informed of the breakdown for their own purposes:

| MES | DMOS |

|---|---|

| Production Execution | Maintenance Execution |

| Contains the production schedule. If a machine has stopped, rescheduling could be necessary. | Contains the task management system, like a breakdown that needs fixing. |

| Manages the product definition and initiates changeovers. | Shortens MTTR by alerting the right people, enabling instant access to the right knowledge and proposes actions to solve the deviation. |

| Calculates the OEE. It needs to track each equipment’s (M)TTR and breakdown categorization. | Manages the entire task lifecycle and connection between them, like deviation and Root Cause Analysis. |

What’s more, in a true digital factory, each system should be connected to the other:

Existing SCADA <-> MES connections

In some plants, SCADA and MES are already connected. This is great, as this already saves the operator time. This connection can stay as is when you introduce a DMOS. The MES sends a breakdown notice to the DMOS, and additional information like the OEE categorization can be synced with the DMOS, as shown in below illustration.

The great thing about a DMOS is that you can also connect it to all kinds of other systems like IoT technology. In case data from several sources overlap rules can be set up to avoid creating duplicate tasks.

Other benefits of a MES – DMOS connection

Next to improved OEE calculation, a connection between your DMOS and MES will decrease downtime. In case of an equipment breakdown, the MES adjusts the schedule to exclude it and the DMOS will notify the right people and helps them solve the issue with instant access to shop floor knowledge. Other advantages are consistent data between systems, which saves valuable time and improves data quality. Data can be shared with third parties too.

Related Articles

Digitize your inspections, audits and checklists

4Industry targets Nordic market via strategic partnership with Advania