Digital Poka Yoke and its value in a factory

Using digital, mobile technology, you can easily introduce the Poka Yoke concept, digitize Poka Yoke steps, and enhance user adoption.

After the introduction of Poka Yoke in the 1960s by Shigeo Shingo, an industrial engineer at Toyota, manufacturers have been using it to reduce inevitable human mistakes and defects in production.

Though the concept is great, many factories are still struggling with implementing it, often due to poor user adoption. Using digital technology, you can easily introduce Poka Yoke, digitize Poka Yoke steps, and enhance user adoption with mobile capabilities. Not only will this help increase your Overall Equipment Effectiveness (OEE), it will also create a safer shop floor and improve knowledge capturing.

Digitizing the Poka Yoke steps

Poka Yoke is all about creating the right conditions before executing a process step, thus preventing defects from occurring.

In cases where this is not possible, Poka Yoke is used as a detective function, eliminating defects in the process as early as possible. This ensures top-quality products and optimizes production lines.

However, many factories are still struggling with implementing Poka Yoke concepts.

Poka Yoke is a mindset, requiring you to follow certain processes. With digital Poka Yoke, you can enhance worker acceptation and maximize its benefits. But note that a digital tool will in no means ever be a replacement for physical signs, railings or other aids to prevent defects or incidents.

Poka Yoke consists of 5 steps:

1. Describe the defect

2. Where’s the defect? Go look at it (“Go to Gemba”)

3. Analyze the defect

4. What’s its root cause?

5. Design and implement tools to avoid recurrence

You can digitize steps 1-4 completely: A tool like 4Industry can help you with Tag/Deviation Management (1) to digitally describe, locate (2), analyze (using 5Why Analysis) (3), and document the root cause (4). Other ways to locate defects are FMEA, SPC and SQC types of activities on the shop floor, all of which are supported by 4Industry.

But documenting root causes alone is not sufficient. Communication to all involved parties is equally important. After communication, the responsible operator/engineer can plan the maintenance activities to ensure the defect will not recur.

Tracking these activities is an integral part of 4Industry. In TPM terms, we’re talking about Autonomous Maintenance here. The Analyze step is part of the Focused Improvement pillar. Both pillars are fully supported by 4Industry.

Avoiding recurrence with digital tools

Next to physical signs, railings and other aids that help prevent defects or accidents, digital Poka Yoke tools can support workers with visual aids and steering mechanisms and fail-safe. Here’s how 4Industry supports this:

Visual aids

Visual aids support operators in making the right judgement call.

There are several ways to show operators which steps they have to take.

Via digital e-ink displays for example, a common and widely used local information display solution, you can display information like safety precautions, lubrication material, operating mode, lockout/tagout (LOTO) information or active work permits per area.

E-ink labels have many advantages. They are affordable, wireless (battery powered) and available in many shapes and sizes. You can also place the displays in different locations and areas of your factory.

Visual steering mechanisms

Based on the operator’s actions, you can visually steer an operator by providing specific information.

Location-based

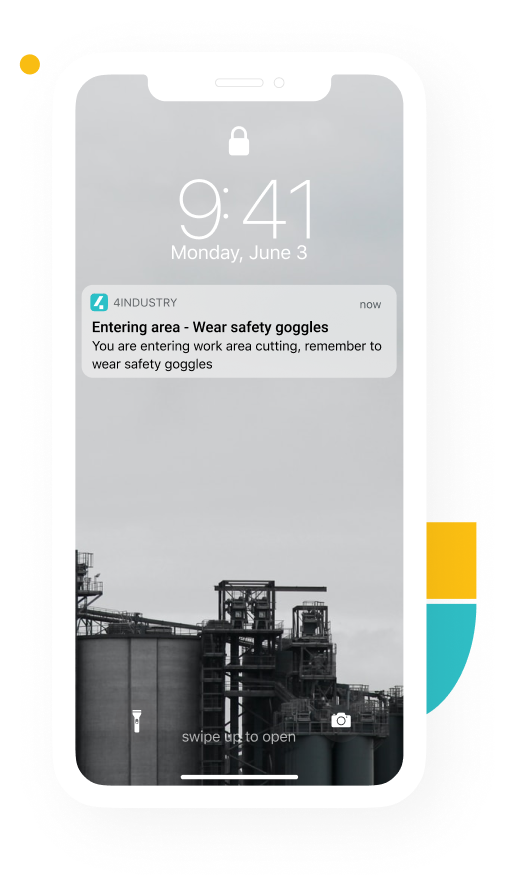

With a mobile solution that includes location-based tracking via iBeacon/GPS/WiFi like 4Industry, you can push notification messages to mobile devices with specific information.

Let’s say a worker enters a certain area where safety goggles are mandatory. When the worker nears the area, the system automatically sends out a push notification “Remember to wear your goggles”.

Standard Operating Procedures

When operators start a standard operating procedure (SOP), they run through the procedure step by step on their mobile devices.

By adding pictures to the steps, they have a visual representation showing them exactly how to perform the tasks at hand, thus minimizing mistakes.

Fail-safe

A fail-safe prohibits a worker from making a mistake. A fail-safe is usually a physical aid, like railings to keep people safe at heights or a lock to prevent opening a closet, etc. A digital tool like 4Industy can draw attention to using these physical aids via push messages, thus preventing injuries

.

Table of Contents

Related Articles

Digitize your inspections, audits and checklists

4Industry targets Nordic market via strategic partnership with Advania