The Six Big Losses: What They Are and How to Minimize Them

Don’t know how to tackle the Six Big Losses in your factory? Here’s how to do this and improve your plant’s OEE at the same time.

Don’t know how to tackle the Six Big Losses in your factory? Here’s how to do this and improve your plant’s OEE at the same time.

Continuous improvement is the backbone of any successful manufacturing operation. Learn in this blog how to continuously improve operations.

Discover how a digital identification, investigation and reporting of Root Cause Analyses can improve your continuous improvement efforts.

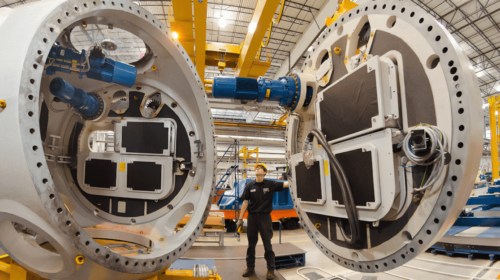

Discover in what ways a digital manufacturing operating system like 4Industry can help you enhance manufacturing efficiency.

Digitized TPM manufacturing processes help you better manage deviations, maintenance, continuous improvement and more.

Manufacturing dashboards display KPIs and other production metrics in meaningful ways to improve operational speed, efficiency and uptime.

Getting your OEE calculation right can be really challenging. But those days are over with a DMOS that interconnects your SCADA and MES!

A playbook for manufacturers that want to know how they can leverage new technologies to increase operational resiliency and production.

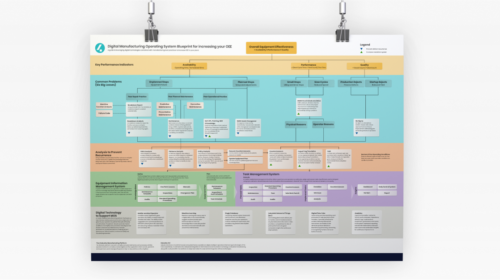

This blueprint explains how a DMOS combined with Industry 4.0, digital technologies and manufacturing best practices can increase your OEE.

Learn how digital Task Management, Deviation Management and Root Cause Analysis can help you achieve a world-class OEE.