The Importance of the Connected Worker in Your Factory

Discover why manufacturers need to transition their operators to connected workers with a digital manufacturing platform.

As manufacturing systems grow more complex, paper-based processes are becoming increasingly challenging to maintain, making them vulnerable to disruptions. One recent example is the COVID-19 pandemic, which has placed significant strain on factories that rely predominantly on manual operations. Investing in connected workers is one way to boost this operational resiliency. Fully immersed in their environments, “connected workers” are supported by connected worker platforms that:

- Enable digital workflows on the shop floor.

- Expedite the sharing of information, knowledge and experiences.

- Facilitate ongoing continuous improvement (CI) within the organization.

- Provide workers with real-time information to guide their actions.

6 Reasons Why its Important to Transition Your Operators to Connected Workers

Here are six reasons why it’s important for manufacturers to transition their operators to connected workers who are supported by these interactive digital platforms:

1. No More Administrative Shift-to-Shift Frustration

Factories typically have a hodgepodge of systems in place to manage production processes including supervisory control and data acquisition (SCADA) systems, Excel spreadsheets, Enterprise Resource Planning (ERP) systems and Manufacturing Execution Systems (MES). Should an issue or breakdown occur, maintenance personnel must address these systems separately, creating a big administrative and technical headache. Having one integrated digital platform that can connect workers to their machines, talk to these various systems and trigger automatic workflows can relieve a lot of this frustration.

Having several manufacturing systems and pen-and-paper processes in place is also inconvenient for operators. Take the simple act of filling out production reports, for example. At the end of their shifts, operators must fill out a paper form and recount anything that happened from memory: “There were 20 minutes of machine breakdowns,” for instance. Operators in the next shift have to then sift through these paper notes or spreadsheets — a process that not only takes time, but also fails to present the information in any meaningful or actionable way.

Using a connected worker platform, the connected worker can simply record and report incidents in real time during his or her shift using a smart device. This information becomes instantly available to subsequent shifts as part of a comprehensive knowledge base, overcoming the friction and communication challenges that can occur between shifts.

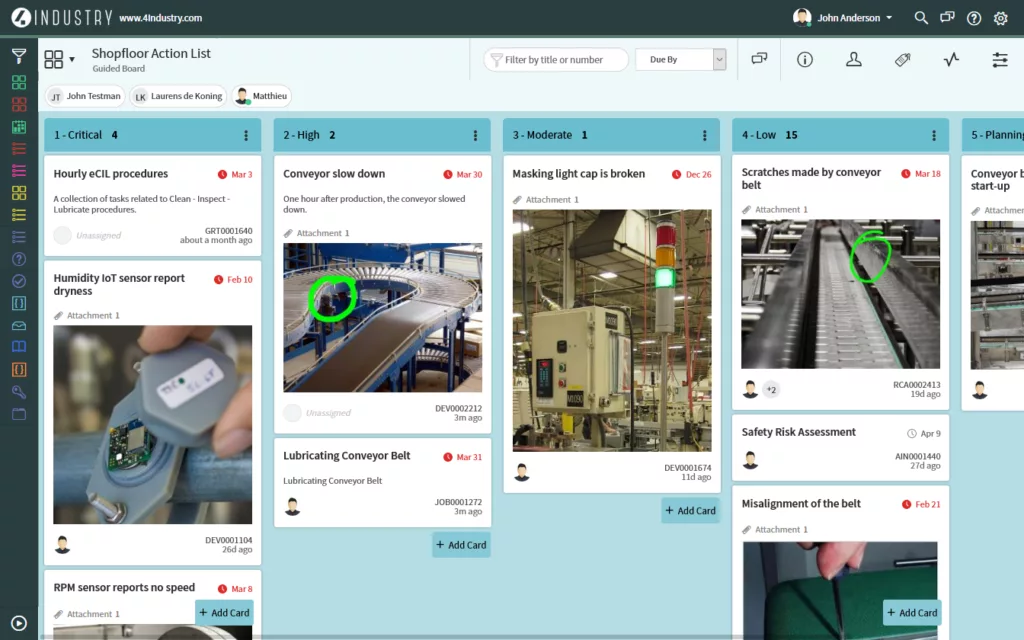

2. Data becomes Actionable With Manufacturing Dashboards

Connected worker platforms use the information provided by connected workers during their shifts — whether deviations, safety, health and environmental (SHE) issues or assessment results — to generate various manufacturing dashboards that provide visibility into formerly siloed processes. By displaying these metrics in interactive, meaningful ways, manufacturers can improve their operation’s speed, efficiency and uptime.

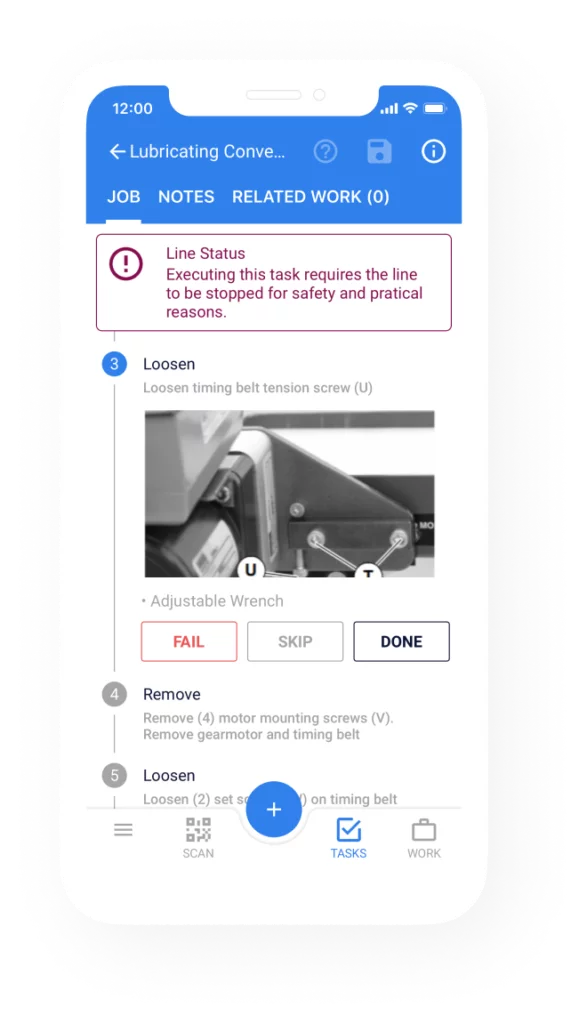

These dashboards also play a critical role in the task management process by breaking down and displaying the jobs that the connected worker can perform at their machine. Supervisors can create and assign cleaning, inspection and lubrication (CIL) tasks to operators directly within the application, for example, and create step-by-step work instructions with accompanying photos and videos. Empowered with this information, workers have all the information they need to complete the task. To check the status of these jobs, supervisors and maintenance personnel can pull up the task management dashboard, which eliminates the need to log into separate manufacturing systems or switch between applications.

3. Incident Sharing is Quick and Easy

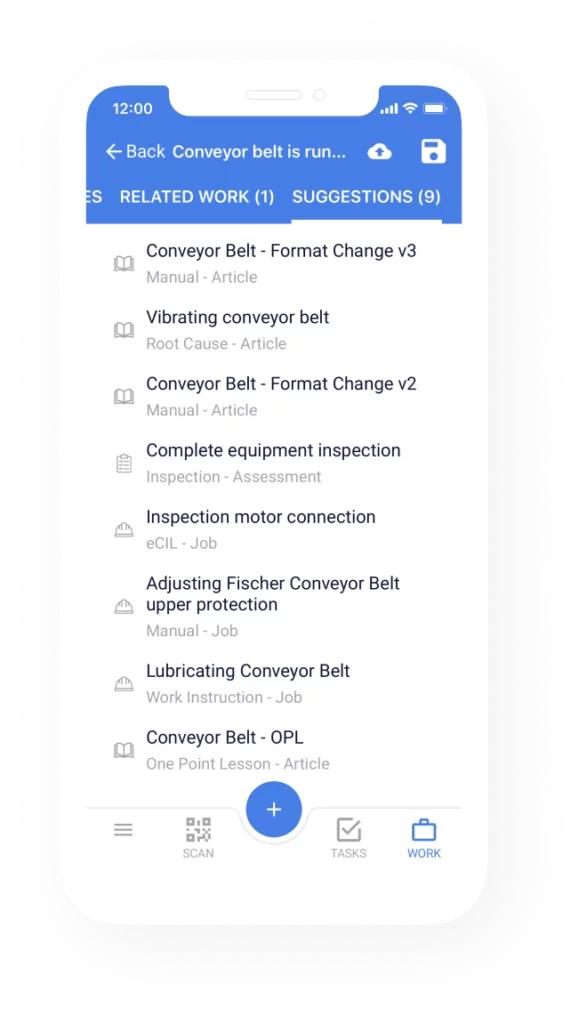

With a connected worker platform, the connected worker becomes an integral part of the deviation management process. When a worker registers an issue, the platform automatically notifies relevant personnel and can automatically trigger a root cause analysis (RCA). If the issue happens again, the platform makes suggestions using tried-and-true items from the knowledge base and also displays the results of prior analyses. Thanks to this feature, workers already have a starting point to resolve an issue, enabling them to solve future problems quickly. For example, after discovering a machine component is vibrating, the worker takes a picture of the machine using his smartphone and inputs details about the issue. The connected worker platform automatically suggests a work instruction — lubricating the machine, for example.

These connected worker platforms can also improve the response times to SHE events. Similar to an equipment deviation, connected workers can register a SHE event as soon as it happens. They can also provide helpful feedback about the issue and participate in the resolution process — all of which is quicker than waiting for a visit from the safety officer in several months time.

4. Connected Workers Make it Easier to Achieve Autonomous Maintenance

Related to the above point, connected workers can easily perform their own maintenance tasks because they’re already connected to all the relevant knowledge they need to successfully perform their jobs — whether scheduled or ad hoc.

Normally, in the event of even the smallest maintenance task, an operator has to call an engineer or maintenance staff member, which wastes valuable production time. With a connected worker platform, connected workers can perform basic CIL tasks, register, resolve and perform audits on their machines and take greater ownership of their equipment. This process increases their knowledge of the equipment and frees up maintenance staff for more complex tasks. It also improves the workers’ ability to identify and correct minor faults before downtime occurs.

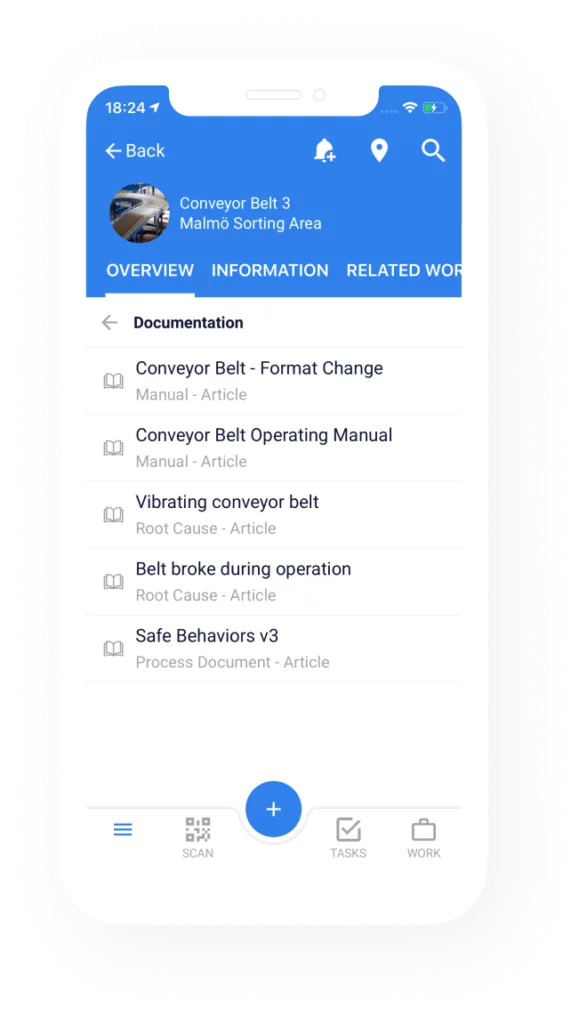

5. Accessing Knowledge and Relevant Documentation is Effortless

Connected workers can access knowledge whenever and wherever they need it — all from the palm of their hand. Thanks to this accessibility, workers avoid having to run to the control room to search for a standard operating procedure (SOP) or other knowledge item, print it out and then carry packets of paper around the factory. They also avoid having to search through endless “digital papers” in OneDrive or check if a file is the correct version.

With a digital knowledge base, the connected worker can enjoy immediate access to the latest SOPs, technical manuals, safety guidelines and other items, all while winning back the time lost to searching for paper-based knowledge. In fact, as it stands, the typical worker spends roughly 20-percent of his or her time looking for and collecting information. Because the knowledge base is intuitive, searchable and mobile-first, manufacturers will also have an easier time training the next generation of connected workers. Newcomers can refer to the knowledge base for on-site training using interactive checklists, pictures and videos, reducing the time it takes to learn new equipment.

6. Digital Workflows Keep Shop Floor Processes Moving

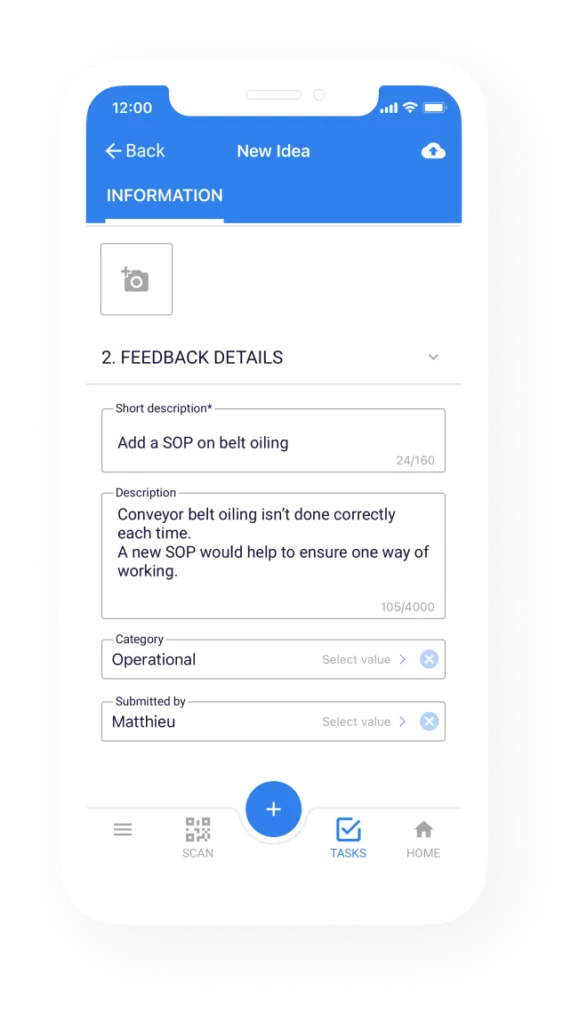

Whether connected workers want to register a new CI idea or report an equipment breakdown, these digital workflow processes no longer take them away from their equipment — keeping all production processes running smoothly. In addition, workers no longer have to contend with various tools like Excel or SharePoint. Having a haphazard collection of tools and systems creates silos, preventing workers from truly reaping the benefits of digital technology.

On the other hand, using one integrated platform like 4Industry that connects and brings data, equipment and workers together will keep your workers connected to their machines — and to each other.

Table of Contents

- 1. No More Administrative Shift-to-Shift Frustration

- 2. Data becomes Actionable With Manufacturing Dashboards

- 3. Incident Sharing is Quick and Easy

- 4. Connected Workers Make it Easier to Achieve Autonomous Maintenance

- 5. Accessing Knowledge and Relevant Documentation is Effortless

- 6. Digital Workflows Keep Shop Floor Processes Moving

Related Articles

Digitize your inspections, audits and checklists

4Industry targets Nordic market via strategic partnership with Advania