How Digital Shift Handovers Improve Communication, Productivity, and OEE

Learn the ins and outs of shift handovers in manufacturing and discover how digital shift handovers improve efficiency and productivity.

Shift handovers play a key part in keeping production flowing smoothly.

If done correctly, they guarantee that each consecutive shift is able to pick up production flawlessly and is aware of any tasks or issues that originated in the preceding shift.

In this blog, we will walk you through everything you need to know about shift handovers. We’ll also explore some of the ways digital shift handovers can improve efficiency and productivity on the shop floor.

What is a shift handover?

A shift handover is a transfer of knowledge between two consecutive work shifts. It is the moment when the outgoing shift communicates all relevant information to the next shift concerning issues, unfinished tasks, and KPIs. Ideally, the handover guarantees that the next shift is able to continue production without encountering any surprises.

Why are shift handovers important?

It’s not uncommon for factories in high-demand industries to run 24 hours a day. Typically, these always-on factories have three consecutive 8-hour work shifts.

Clear and structured shift handovers are especially important in these types of factories.

Essentially, a shift handover is an exercise in good communication.

For example, if an operator forgets to mention an issue during his shift handover, the operator in the next shift may spend precious time doing things that have already been done, like notifying maintenance or investigating the root cause.

On the human side, this leads to frustration, a breakdown of team spirit, and the formation of silos.

Furthermore, the factory itself suffers from waste, productivity loss, and sub-optimal efficiency.

What is a shift handover report?

A shift handover report is a document that encapsulates all essential information about a shift. The exact contents of a shift handover report will vary per factory, process, or company.

Generally, however, a shift handover report will cover:

- General information on the shift like time, date, personnel, line

- SHE information: issues, work permits, etc.

- KPIs like OEE; changes to equipment settings; changeovers

- Issues that occurred during the shift like deviations and defects

The downsides of verbal and paper-based shift handovers

Using an adequate data collection method is a prerequisite for performing a good shift handover, as this ensures that all relevant information is available to the next shift.

In many cases, this is done verbally, making the success of a handover dependent on an operator’s memory. In other cases, it is done on paper, which often includes the process of recapturing that data in a digital format like Excel.

Even if done conscientiously, these non-digital shift handovers are error-prone.

As already mentioned above, it’s all too common that an outbound shift—weary from their labor—forgets to pass on vital information.

Furthermore, paper shift handovers make it difficult to store, aggregate, and analyze data relating to KPIs, machine settings, and so on.

To remain competitive in today’s market, it is becoming more and more important to eliminate work that reduces efficiency or quality. To ensure an optimally streamlined shift handover process, it is therefore a best practice to use a dedicated, virtual tool to automate this process and make it fail-proof.

How to automate shift handovers with a Connected Worker Platform

A Connected Worker Platform like 4Industry enables manufacturers to digitalize their shift handovers, allowing them to discard their paper-based forms and start working with a highly automated, mobile-enabled application.

Our Smart Forms module lets manufacturers create custom checklists that enable operators to record all necessary information for a shift handover straight on the shop floor.

This safely eliminates the risk of them forgetting any vital information while also improving their efficiency, as it’s no longer necessary to leave their station to write down information or recapture it in another system.

Digital checklists are scheduled and assigned automatically, eliminating the probability of not having the necessary information available.

These checklists also enable manufacturers to capture data that cannot be captured automatically by MES systems, like that of analog devices that do not have digital communciation capabilities.

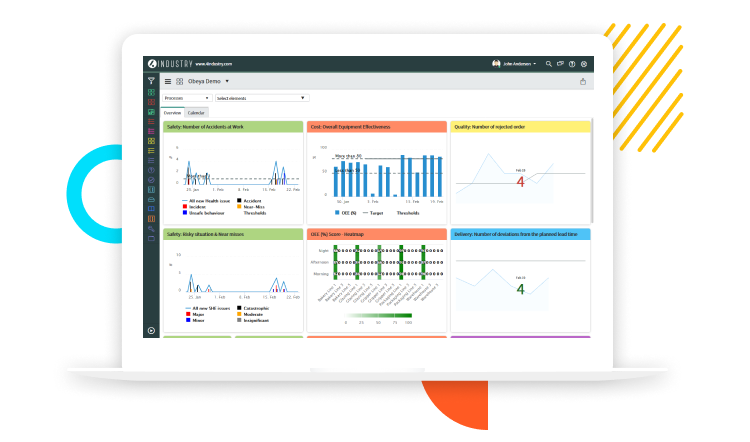

The great thing about digital shift handovers is that all data is stored in a central database. It can therefore be automatically aggregated into dashboards that can be used to convey information during a shift handover.

Ultimately, connected worker software creates a shift handover process in which everything that happened during the outbound shift is clearly communicated to the succeeding one.

The risk of operators doing redundant work is lessened and problems are followed up on and solved quicker, leading to efficiency gains.

The benefits of digital shift handovers in a nutshell

- Reduced waste & increased productivity

- Higher OEE

- Immediate data capturing on the shop floor

- Ability to capture analog data

- Improved employee satisfaction

Related Articles

The 4Industry Everest release is here!