Kaizen: A Complete Guide

Learn everything you need to know about Kaizen in manufacturing, the Japanese continuous improvement mindset every manufacturer should use.

What is Kaizen in manufacturing?

In manufacturing, Kaizen is a business philosophy in which everyone in an organization is involved in the effort to improve things incrementally. ‘Kaizen’ is the Japanese word for continuous improvement—zen meaning ‘for the better’, and kai meaning ‘change’—and the two terms are basically synonymous. Although many think Kaizen is a method, it is actually more of a mindset—a mindset that can go paired with certain methods and techniques like 5S and the PDCA cycle.

In this post, you’ll find everything you need to know about Kaizen in manufacturing. We’ll start of with a brief history, then explain how manufacturers implement and use Kaizen, and conclude by answering some frequently asked questions (like how Kaizen differs from Lean and Six Sigma).

Now, let’s explore the ins and outs of Kaizen!

What is the history of Kaizen?

Although Kaizen is a Japanese concept, its origins lie in the United States during World War II. Due to the immense time-pressure and scarce resources, it was impossible for manufacturers to implement any radical, large-scale improvements to production. Instead, the opposite approach was taken: manufacturers made minor improvements that were easy to be implemented—ideally on the same day an opportunity for improvement was detected.

Let’s go forward a few years. We’re now in post-World War II Japan. The U.S., acting under the Marshall Plan, is helping Japan rebuild its manufacturing industry and improve its managerial capabilities. Because of this, the Japanese took over the continuous improvement mindset that was developed in the States during the war—and thus, Kaizen was born.

What are the 5 elements of Kaizen?

Kaizen is characterized by a distinct set of principles:

- Teamwork

- Personal discipline

- Improve morale

- Quality circles

- Suggestions for improvement

Let’s quickly walk through these one by one.

1: Teamwork

All employees, from shop floor operators to a company’s CEO, should have a shared continuous improvement mindset.

2: Personal discipline

Kaizen heavily emphasizes the person responsibility of all employees. It requires everyone to be high-performing at work and insists that employees are punctual, diligent, and attentive.

3: Improve morale

Morale should be and stay high among employees. This means that management should provide them with the right workplace conditions and facilities to make workers feel happy. Furthermore, workers should not be burdened with an overload of work and should be rewarded for their performance.

4: Quality circles

A quality circle is a group of employees that regularly meet to discuss ideas for improving a business. It is important that all sorts of employees are involved; again, from the frontline workers to the leadership staff.

5: Suggestions for improvement

A system should be in place where employees can give feedback and share their ideas about improving the business. An idea box is a classical example of this, although these days this often takes a digital form. Ideally, ideas should be acted on and implemented and employees that give feedback should be credited for their work; if this is not done, employees might become demotivated because they aren’t being listened to.

What types of Kaizen are there?

Kaizen is often subdivided into a set of types. These extend from small, on-the-spot improvements to large, organized projects.

Let’s explore each type of Kaizen individually.

Point Kaizen

Point Kaizen happens on the spot, quickly and without any preparation. When an operators notices a deviation, breakdown, or any other type of problem, measures are instantly taken to fix it. Although seemingly trivial, the aggregation of Point Kaizen activities can have a significant impact on shop floor performance over time.

System Kaizen

System Kaizen is a more organized form of Kaizen. It consists of planned events and looks at systemic and strategic problems in an organization.

Line Kaizen

Line Kaizen connects departments that are involved upstream and downstream of a process. For example, if a procurement department (downstream) organizes a Kaizen event, the planning department (upstream) should be involved as well.

Plane Kaizen

Plane Kaizen changes the department lines of Line Kaizen and turns them into so-called value streams. This results in a complete overview of all the steps that are taken in the manufacturing of a product. In Kaizen, a value-stream map allows changes to one line to be applied to all the other lines that form the plane.

Cube Kaizen

Cube Kaizen connects all planes to each other and results in an organization that is entirely saturated in the Kaizen mindset. Improvements can be made anywhere, both upstream and downstream, as well as to other aspects of a process, like suppliers and logistics.

What is 5S?

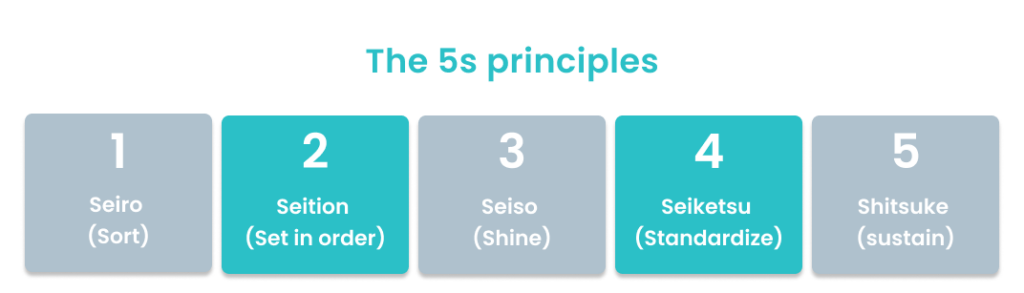

5S is a method in Kaizen and lean manufacturing to organize, tidy and standardize workplace activities. The consists of 5 principles that each start with the letter S, both in Japanese and in English:

- Seiri (Sort)

- Seition (Set in order)

- Seiso (Shine)

- Seiketsu (Standardize)

- Shitsuke (Sustain)

5S is used to create an organized, clean and structured workplace. Let’s quickly explore each S one by one.

- Seiri (Sort)

This step looks at all tools, materials, and equipment in an area and evaluates what is necessary and what can be discarded (or stored elsewhere). To determine this, the people that work in the applicable area need to be involved. For each item, it’s necessary to evaluate how often it is used, what it’s purpose is, who uses it, and, ultimately, if it is necessary to keep it in the area.

- Seition (Set in order)

The remaining items can now be organized and stored. It is important to keep items in a place close to where it is used most frequently. Furthermore, it is possible to group the different items required to perform a task and categorize them with a color-coding system.

- Seiso (Shine)

No one likes a messy workplace, but in the heat of production, grabbing a mop and cleaning a floor isn’t always in the front of an operator’s mind. This is, however, not a trivial step. An clean workplace isn’t only nice to work in, it can also improve employee safety. This step also involves the proper maintenance of machines and therefore has effect on preventing breakdowns and improving performance.

- Seiketsu (Standardize)

You probably know the phenomenon: in a sudden burst of inspiration, you decide to clean up every inch of your messy apartment, only to realize a month later that everything is messy again. The same applies to the shop floor. It’s great to do an extra thorough clean once in a while, but you can only maintain the state of shop floor if you organize your cleaning (and maintenance) activities. Cleaning activities should therefore be turned into scheduled tasks. This turns sudden events into standardized routines, and ensures your shop floor is always shiny.

- Shitsuke (Sustain)

Similar to above, this step ensures that all personnel continually pay attention to performing and improving the above four steps. This ensures that 5S becomes a long-lasting organizational mindset instead of an irregularly occurring phenomenon.

The 7 Types of Waste (Muda) in Kaizen

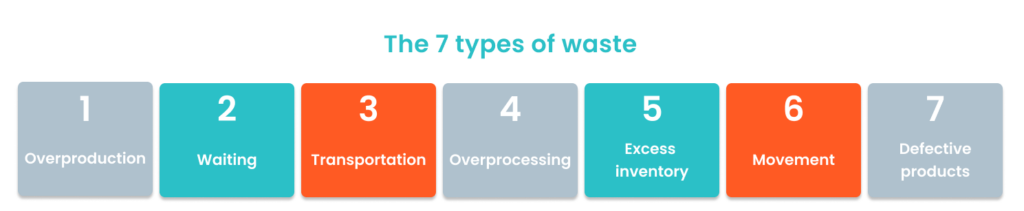

Kaizen, like Lean, is focused on eliminating wasteful activities in an organization. These are often categorized into 7 types of waste, called Muda in Japanese:

- Overproduction

- Waiting

- Transportation

- Overprocessing

- Excess inventory

- Movement

- Defective products

- Overproduction

Producing too many goods should be avoided so as to reduce costs related to the storage, inspection, and throwing away of (unused) products. This can lead to a tremendous loss of efficiency, productivity, and profits. Just-in-time manufacturing deals with exactly this problem by only producing products that have been ordered.

- Waiting

Waiting entails time that is lost because workers (or machines) are idle. Processes should be designed to eliminate any idle time.

- Transportation

Moving things around unnecessarily similarly impacts efficiency and productivity. It’s no use moving a part from area A to area B to perform a small action on it, only to return it back to area A.

- Overprocessing

Overprocessing is the act of adding parts to a product that have no value to its end-user. It’s for instance unnecessary to add features to a product that are of no interest to the consumer. Furthermore, adding details or coloring to parts of a product that will not be seen by a customer should be avoided.

- Excess inventory

Similar to overproduction, manufacturers should not order any materials that are not needed for production. Again, the just-in-time principle applies here: inventory should only be kept to produce something that has been ordered.

- Movement

Unnecessary movement, whether by machines or people, leads to waste of time. 5S comes into play here. Areas should be organized so that all tools and documentation necessary for production are within reach.

- Defective products

Last but certainly not least, producing defective products leads to a complete waste of time and effort. If defective products need to be reworked or discarded, the organization suffers from a loss of output, efficiency, and profit.

Examples of Kaizen in manufacturing

Let’s now look at some examples of the real-world application of Kaizen.

- During a Gemba walk, a manager notices that a crew of operators is idling for an extended amount of time. They tell him they do this because they can’t go back to work until a batch of products arrives. Through a Kaizen event involving people from planning, procurement, and the shop floor, changes are made to the process to allow the operators to start working on that batch immediately.

- An assembly line is running at sub-optimal efficiency. Upon inspection, it’s discovered that operators spend a lot of time walking to another station to grab a tool, which is often in use by another crew. By ordering new tools and placing them near the assembly line, the problem is fixed.

- Production is often halted because a certain machine breaks down. After a Kaizen event, it’s discovered that it isn’t being maintained properly and that its parts are worn out. By scheduling regular maintenance, the machine is taken proper care of and doesn’t break down anymore.

How to implement kaizen in a factory

Now that we’ve explored the basics of Kaizen in manufacturing, you may be wondering how you can start implementing it in your organization. Naturally, we can’t go into extreme detail here, but we’ll provide you with some handy tips to get started with Kaizen in your business.

- Get everyone on board

Kaizen isn’t just a thing for supervisors or managers; everyone in an organization needs to be involved. Everyone needs to be aware that Kaizen is an incremental process with seemingly insignificant improvements. However, if they can keep in mind that the results, over time, will be anything but trivial, motivation and morale will stay high.

- Ask for feedback

Feedback is key to Kaizen. Everyone needs to be able to give their opinion on all sorts of matters, whether relevant to their duties or not. It’s crucial to put systems in place that allow employees to give feedback, from a simple idea box in the cantina to a more structured digital feedback system. Remember to respond to feedback, whether it was useful or not, as employees will be discouraged from giving feedback if it is ignored or not acted upon.

- Brainstorm and come up with solutions

A crucial component of Kaizen is the so-called Kaizen blitz or Kaizen event. In this, representatives from different departments get together for an extended amount of time to discuss how to address certain problems. In a Kaizen blitz, root cause analysis and continuous improvement tools can be used to find the origin of issues, brainstorm, and think of solutions.

- Implement a solution

When a solution has been thought up, it’s time to implement it. Seems obvious, right? However, this isn’t as straightforward as it seems. People often hesitate to implement solutions by overanalyzing a problem or over-extending the scope of a solution. It’s a best practice here to seek a quick and easy-to-implement solution and apply it on a small scale. If successful, it can be expanded on and applied to a larger part of the business.

- Rinse and repeat

Was the solution successful? If not, return to the drawing table and think of other solutions or use alternative solutions thought up during a blitz. If successful, as already said, it’s time to implement the solution on a broader scale.

How a Connected Worker Platform improves Kaizen in manufacturing

At 4Industry, we often get asked if a Connected Worker Platform like ours can do anything to improve Kaizen in a factory. In short, the answer is both yes and no. As we’ve emphasized in this article, Kaizen is an organizational mindset that needs to be fostered constantly, which cannot be done by the magic wand of digital technology.

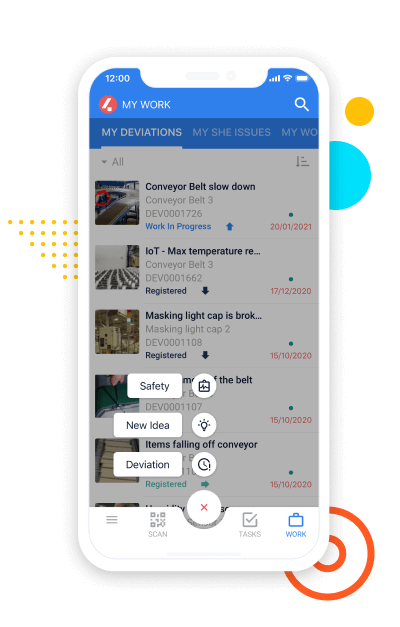

However, Connected Worker Platforms do contain certain features that facilitate or even stimulate behavior that is crucial to Kaizen. Let’s go through one important example.

Digital feedback system

The great thing about a Connected Worker Platform like 4Industry is that it allows shop floor operators to instantaneously give feedback. In 4Industry, users can give feedback on anything in the app, whether it’s a knowledge article, task, or machine manual. Feedback is automatically sent to the relevant person, who can easily evaluate it, organize it, and aggregate it into a larger improvement project.

The key things here are simplicity, structure, and storage. Feedback is given easily; it only takes a few taps of the finger and can be done on the spot. An operator doesn’t have to walk to the idea box and thereby doesn’t risk forgetting his idea. Unlike scraps of paper, digital feedback isn’t easily lost and can be evaluated and overseen much more easy.

The pros and cons of Kaizen in manufacturing

Here are some advantages and disadvantages of Kaizen in manufacturing.

Pros

- Improves teamwork and team spirit

- Increases efficiency and productivity

- Creates standardized work

- Is focused on improving employee satisfaction

- Improves safety

- Reduces wasteful practices in an organization

Cons

- Requires the involvement of every employee and is therefore dependent on individual character

- Changes to routines and habits may be hard to implement

- Training and knowledgeable professionals are needed to implement Kaizen in an organization

Frequently asked questions about Kaizen

Is Kaizen the same as Lean?

No. Kaizen is a continuous improvement mindset, while Lean manufacturing is focused on eliminating waste and boosting productivity. However, the two are similar in a lot of aspects and sometimes have similar tools and techniques.

Is Kaizen the same as Six Sigma?

No. Kaizen is focused on creating a shared organizational mindset to continually improve every aspect of the business. Six Sigma, on the other hand, aims to reduce the number of defective products that an organization produces.

Are Kaizen and 5S the same?

No, Kaizen and 5S are not the same. 5S is a technique that is used in Kaizen to organize a workplace, while Kaizen is an organizational philosophy focused on continual improvement.

Table of Contents

- What is Kaizen in manufacturing?

- What is the history of Kaizen?

- What are the 5 elements of Kaizen?

- What types of Kaizen are there?

- What is 5S?

- The 7 Types of Waste (Muda) in Kaizen

- Examples of Kaizen in manufacturing

- How to implement kaizen in a factory

- How a Connected Worker Platform improves Kaizen in manufacturing

- The pros and cons of Kaizen in manufacturing

- Frequently asked questions about Kaizen

- Sign up for our latest connected worker updates

Related Articles

Features

Manufacturing Glossary