Digital Work Instructions: a Complete Guide

Discover everything you need to know about digital work instructions, including their benefits, use cases, and the best software for creating them.

What are digital work instructions?

Digital work instructions are virtual versions of printed work instructions. Where work instructions are usually created in Word, Excel, or PDF, digital work instructions are made in dedicated digital work-instruction software and made accessible on various smart devices through a Connected Worker Platform.

In this article, we’ll explore how work instruction software enhances regular work instructions and can help organizations improve standardization, productivity, quality, and more.

Without further ado, let’s explore the ins and outs of digital work instructions!

The use cases for digital work instructions

You may be wondering why you should upgrade your paper-based work instructions to digital ones: Apart from assisting operators in completing their tasks, are there any other use cases for digital work instructions?

There are, in fact, many—ranging from standardizing work to capturing data. Let’s walk through these one by one.

Standardized work

When work instructions are on paper, it’s challenging to maintain standardized work in a factory, as it is difficult to update documentation factory-wide. If it’s necessary to change a work instruction, numerous stacks of paper have to printed out and distributed. It naturally then becomes difficult to guarantee that all outdated documents are no longer used; if a change is especially important, e.g. to safety, the use of outdated work instructions can have significant negative consequences and even compromise regulatory compliance.

With digital work instructions, updates can be effected instantaneously factory-wide. All changes are tracked in the system and undergo the appropriate approval flows, guaranteeing compliance. Operators can receive a notification when a change is made, so they don’t continue working in the old way out of habit.

Training and onboarding

Simply said, anyone with the right skills should be able to follow a work instruction and thereby complete a task in the intended way.

The great thing about digital work instructions is that they are much more media-rich than regular ones.

An image speaks more than a thousand words, and paperless work instructions can contain both images and videos. This greatly facilitates the training and onboarding process within factories.

Furthermore, learning through shadowing a seasoned operator can be largely eliminated, as a richly visual work instruction enables a new operator to learn and complete tasks autonomously.

Preserving tribal knowledge

The previous use case can only work if you have a digital knowledge base containing all of your factory’s standard operating procedures.

Some of these will have already been recorded on paper, but others will be, so to say, in your experienced operators’ heads—so-called tribal knowledge.

Digital work instructions allow you to capture this valuable experiential knowledge and save it for the benefit of future, inexperienced generations.

However, a common issue with regular work instructions is that they take a long time to create.

Instead of them having to fuss with Word or Excel, the best work instructions software should therefore enable your operators to create new knowledge quickly and without frustration.

Agility

Factories, machines, and manufacturing IT systems are becoming increasingly complex.

What’s more, these times of unstable supply chains, de-globalization, and increased demand for customization call for production to be adaptable to shifting circumstances.

The great thing about digital work instructions is that they enable your operators —whether seasoned or new—to quickly learn to do unfamiliar things, sometimes even without undergoing training.

Why? Well, as described above, because digital work instructions are much easier to follow due to the inclusion of images, videos, and so on.

Ultimately, they therefore empower manufacturers to quickly adapt to a changing market without the need for an elongated process of transition—in other words, digital work instructions bring about much more agile operations.

Continuous Improvement

Digital work instructions can be a great data source for continuous improvement teams.

When part of a larger Connected Worker Platform, it’s possible to track how long it takes to execute an entire work instruction as well as its individual steps.

This enables you to zoom in on and locate inefficiencies that are part of the work instruction itself or the process it falls under.

Data capturing

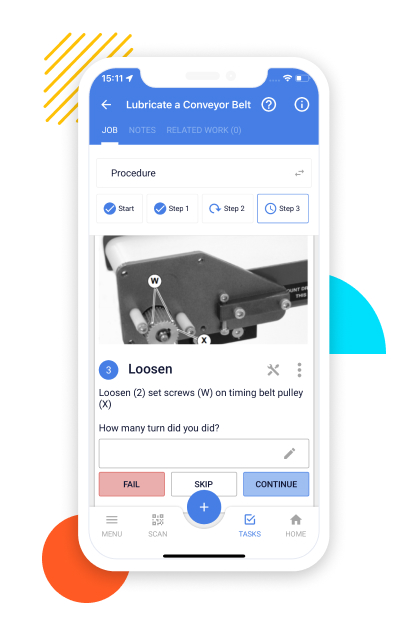

Work instructions often require operators to record data. Digital work instructions enhance this process by enabling operators to do that straight from their smartphone or tablet. 4Industry’s digital work instruction module, for instance, supports multiple input types like pictures (that can be drawn on), text, numbers, and scales.

The benefits of digital work instructions

Now that we’ve explored the use cases of digital work instructions, let’s explore some of their benefits.

Instant updating

Updating a paper-based work instruction is a laborious process.

Whether you want to change a single typo or an entire document, you have to print out a new version, distribute it, and ensure that the outdated versions are discarded.

Digital work instructions can be updated immediately factory wide, ensuring your operators always use the most current information.

Approvals

Digital work instruction software has automated approval flows that guarantee a new instruction or a suggested update is approved by the relevant person.

Because everything is stored in a central database, any data is traceable and instantly retrievable at any time.

Media rich

As already mentioned, digital work instructions can be embedded with videos and images.

It’s also worth to mention the other media types they support, like tables, attachments, and dynamic scales.

Safety

Digital work instructions can be combined with safety instructions so that operators are always aware of required PPE, LOTO level, and safety measures related to a certain task. To boost safety even more, a work instruction can have a safety manual as an attachment.

How to create digital work instructions

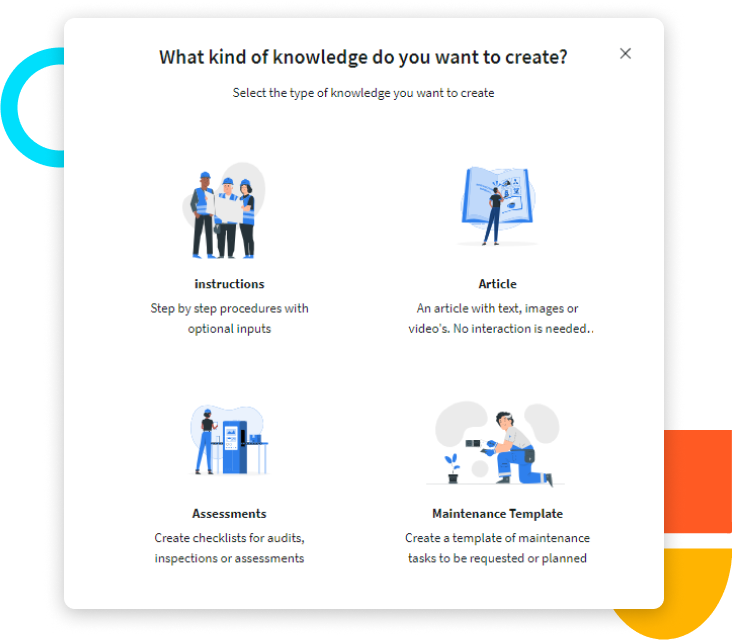

The exact process of creating a digital work instruction differs per software. Let’s take 4Industry’s digital Knowledge Builder as an example.

It’s famously frustrating to build work instructions with Word or Excel, and 4Industry’s Knowledge Builder therefore uses an intuitive drag-and-drop system. Any type of input, whether it’s text or media, can be easily slid to where it needs to go.

To make the process of creating a work instruction even easier, 4Industry allows the creation of templates. This way, a work instruction—or any type of knowledge article—does not have to be built entirely from scratch.

Once a work instruction is created, automatic approval flows pass it on to the appropriate person to be authorized. This ensures the work instruction is of top quality and adheres to (external) regulations.

Frequently asked questions about digital work instructions

How can I digitize my work instructions?

Digital work instruction software enables you to quickly digitize your current work instructions. In our opinion, good work instruction software should have the ability for the creation of templates. Templates, namely, will enable you to quickly digitize your existing work instruction archive, while facilitating the easy creation of new work instructions in the future. 4Industry’s Knowledge Builder, for example, allows shop floor workers to create work instructions, knowledge articles, and assessments in a matter of minutes.

Can my operators use digital work instructions on mobile?

Yes. Digital work instruction solutions like 4Industry work on mobile as well as other smart devices like tablets and wearables.

Can I use visual media in my digital work instructions?

Yes. Digital work instructions can be embedded with images and videos. They also allow for the inclusion of attachments, audio recordings, and different input types.

How do I make sure my work instructions are compliant?

Work instruction software with an integrated audit trail guarantees that any work instruction within your factory remains compliant with regulations. 4Industry, for instance, has automated approval flows that ensure that the relevant people review, approve, and sign off on newly created work instructions and changes to already-existing ones. Everything within the app is tracked and recorded, so you’ll always know who made a change, when they made that change, who approved a new work instruction, and so on.

Related Articles

Machine Learning

Knowledge Management on the factory floor