The Augmented Worker and its vital role in successful 4.0 strategies

Are you stuck in the pilot phase of Industry 4.0? Then you probably forgot to include the Augmented Worker in your strategy!

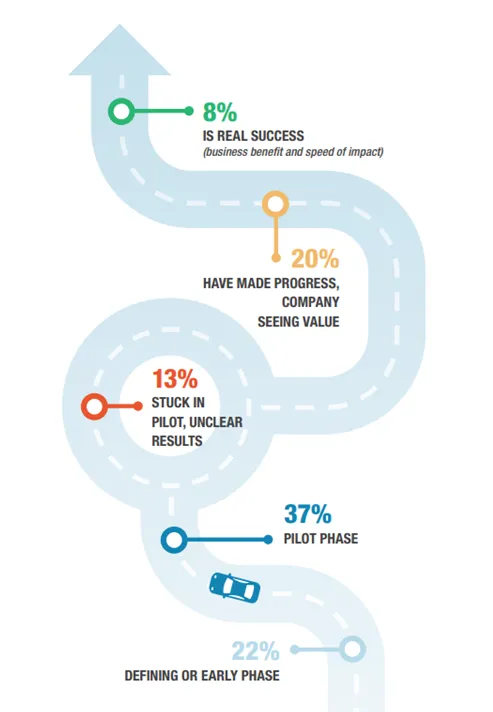

Industry 4.0 has been around for some time now. But a shocking 8% of manufacturers has booked real success with their Industry 4.0 strategy. Most, 71%, are or get stuck in the pilot phase. So, what’s happening here? All mainstream Industry 4.0 strategies forgot one thing: bringing new technology to a factory also involves a culture shift. Workers need to understand and adopt the new technology. If they don’t, Industry 4.0 technology will never bring you the intended results or benefits. The key to a successful 4.0 strategy is the Augmented Worker. Here’s why we think you should focus on the operator, not the technology.

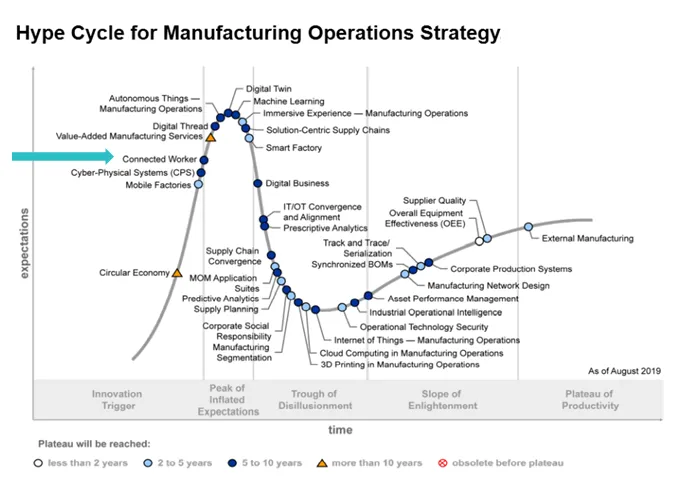

Gartner got it right

They included the Augmented Worker—also called the “Connected Worker”—very early in the Hype Cycle for Manufacturing Operations Strategy. It means you should focus on bridging the gap between your workers and equipment, aiding operators in using new technologies, applications and digital tools to perform their jobs.

Why so many are stuck in the pilot phase

We know that most of you are stuck in the pilot phase:

But what’s causing this? In over 70% of the cases, this is due to a lack of resources and knowledge to scale the technology solution. A handful of tech enthusiasts know all about it, but the majority of the workforce hasn’t got the hybrid/soft skills and digital know-how needed to operate the new technology. Before you know it, you’re left with a state-of-the-art manufacturing apparatus with uninvolved and unmotivated operators to run it!

Shift your focus to the operator

So, the key here is to make Industry 4.0 technology as accessible as possible, to get your employees involved. Augment workers with the tools and information to operate the new high-tech information systems. Otherwise, your investment in information systems will fall flat.

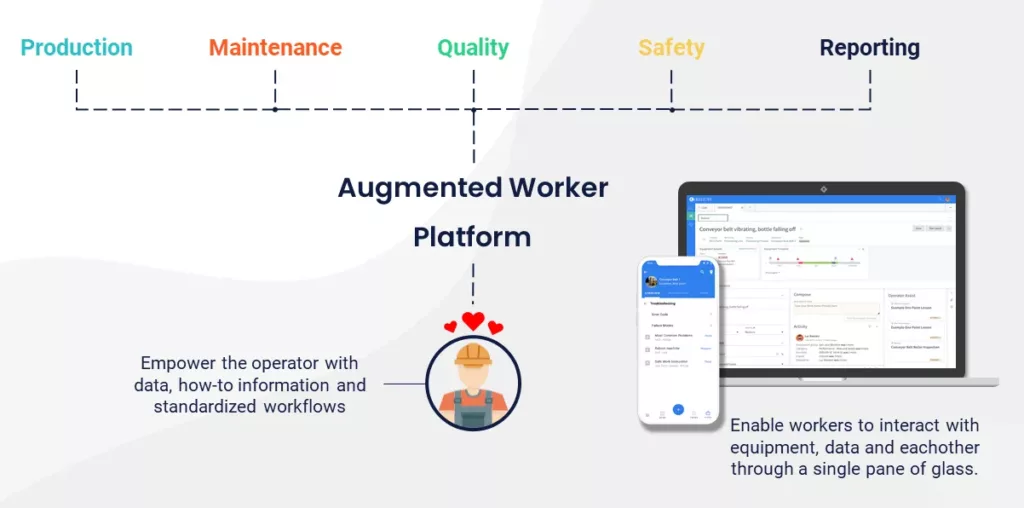

Now, let’s look at this problem from the operator’s perspective. Study the overview below and you’ll soon figure out where the actual problem lies!

Operators have to work with too many tools like SAP, Excel, SharePoint, custom app X and Y and paper to accomplish different types of work. This causes work to be done in silos, because all of these tools are in disintegrated systems. They aren’t connected to one another. An overarching system that connects and brings your data, equipment and workers together, is missing.

An Augmented Worker platform

If you really want to augment your workers, you need a single, user-friendly and mobile-ready platform that connects all of your equipment and technologies to your workers on the shop floor. One that simplifies and structures work processes in a manageable and efficient way. Below overview gives you an idea of how shop floor processes can be brought together in categories like: Operations, Maintenance, Quality, Safety and Reporting.

An Augmented Worker is also an autonomous worker

Why focus so much on augmenting workers? Because it’s also in line with Autonomous Maintenance, part of the TPM and TQM philosophy. A methodology that has proven to be highly effective.

If you empower your workers to perform standard work procedures autonomously, this will help you achieve production efficiencies. The key to successful Autonomous Maintenance? Knowledge Management. If you equip your operators with instant access to digital interactive SOPs with pictures and videos and feedback fields, this will allow them to collect and share shop floor information across all of your plants. Imagine a defect occurs in plant X. The operator registers its details and solution digitally. If the defect occurs in plant Y too, the system recognizes the defect and auto-proposes solutions based on historic data. All the operator has to do is execute it!

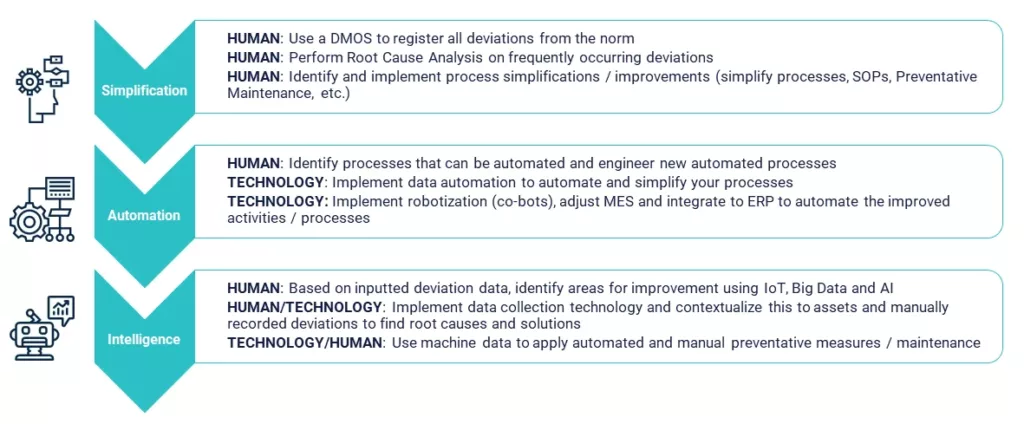

Note how above defect example started with the operator inputting information into a system? It doesn’t start with technology, but with your people providing context. Here’s how this could look like:

Operator effectiveness

A single platform with a uniform desktop and mobile interface will help you increase operator effectiveness. With all shop floor processes in one application, they have a single source of truth. Moreover, with time-saving features like chat and drag and drop work prioritization, they can save time. Lots of time. For a global beverage manufacturer, introducing a digital platform decreased their MTTR from 26 to just 6 days, along with many other benefits!

How to base your 4.0 strategy on the Augmented Worker

If you, just like Toyota and us, believe that you should take the human-centric approach for achieving production efficiencies, here’s how to get cracking.

1. Assess your 4.0 maturity level

Determine how far you’re down the 4.0 journey to determine next steps and prioritize to create most value. Use the Acatech Industrie 4.0 Maturity Index for this.

2. Rethink your 4.0 strategy

Ensure your strategy is centered around the operator and their unique work processes in your factories.

3. Implement an Augmented Worker platform

Ensure you implement a worker-oriented platform—preferably mobile-enabled—that connects the dots between operators, equipment, sensors and technology. Start with Simplification, then switch to Automation and finally throw Intelligence into the mix:

4. Reap the benefits!

Getting your 4.0 strategy right will help you achieve many benefits: from an increased OEE, decreased MTTR to greater operational resiliency to avoid disruptions like COVID-19.

Related Articles

How to ensure social distancing in manufacturing

4 Ways digital helps manufacturing during COVID-19