Standardize work & shorten adoption

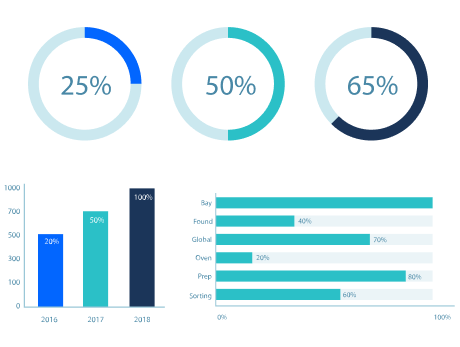

Work standardization helps operators and engineers execute tasks in the exact same way every time, increasing execution quality and operator performance. Thanks to visual information like videos and photos, digital work instructions also serve as interactive training material. Furthermore, you can measure performance through them and integrate them with other shop floor tools.

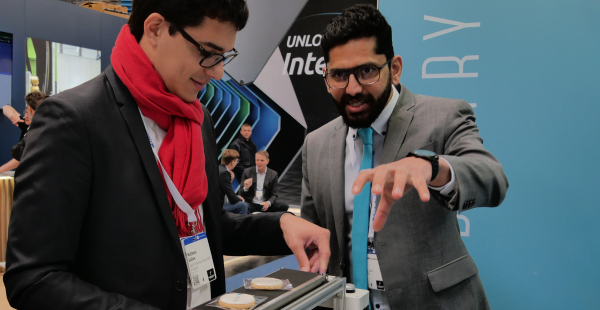

Digital work instructions in action

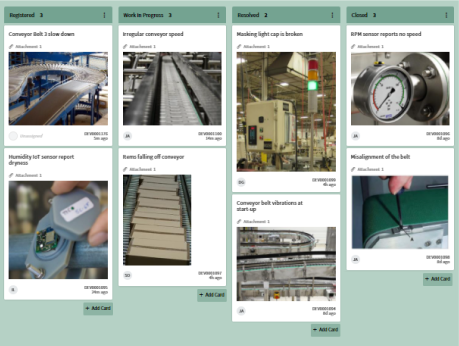

A safer factory floor

Our platform helps employees stay safe by sending them notifications about required PPE, hazards needed, LOTO level, or required line status that automatically pop up when an operator scans equipment or starts a procedure. If you want to provide even more information, you can easily link safety manuals to work instructions.

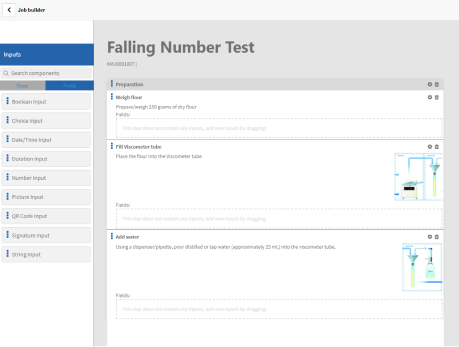

Capture information

Many work instructions or Standard Operating Procedures (SOPs) require operators to record data. Our digital work instruction module enables them to do this straight from the digital SOP on their smartphone or tablet.

12 input types incl. Pictures, Text, Numbers, Percentage, and Scale

Verify inputs immediately to show incorrect parameters and automate follow-up actions like supervisor or engineer notifications

Start integrations from any work instruction step, e.g. notifying your ERP system of supply chain issues by the click of a button

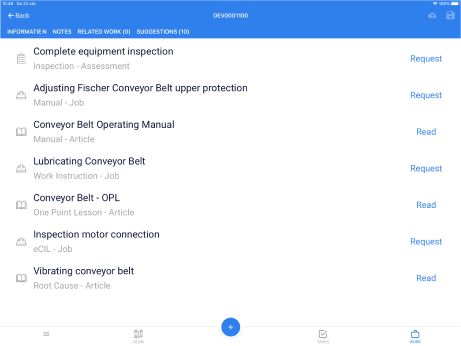

Work Instructions are linked to other platform features

Automation Designer

Our work instruction module and Automation Designer features are linked. This means you can auto-initiate digital work instructions from MES data, inspections or deviations. No matter what your flow is, build it with our designer!

Share best practices

4Industry uses a single database across all of your factories, which means plants with similar equipment can share SOPs, best practices, and so on.