Inspections

Detect, solve, and register breakdowns quickly and easily

Notify operators instantly about breakdowns and attach the right knowledge for a quick fix—all fully automated.

Paper slows down operations…

In most factories, operators aren’t connected with SCADA or MES systems, leading to a high Mean Time to Detect (MTTD) when a breakdown happens.

Searching for the right knowledge to fix a breakdown takes up valuable time, lowering productivity and OEE.

And the subsequent paperwork makes dealing with breakdowns a drudge, leading to unhappy operators and inefficient operations.

…connectivity increases speed

By integrating our mobile-enabled Connected Worker Platform with your manufacturing IT systems, operators are instantly notified when a breakdown happens.

Through Machine Learning, the system automatically attaches the right knowledge to solve the issue at hand, allowing for a quick fix.

What’s more, all administrative work like reporting and maintaining Incident Management systems is done automatically—enabling your operators to focus on value-added work.

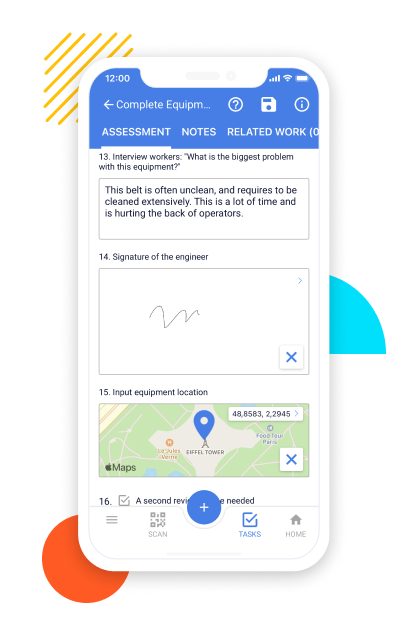

Digital inspections in action

Connected Worker Platforms eliminate all unnecessary manual steps from the inspection process. Detecting, registering, and reporting breakdowns can be done straight from a handheld device.

Escalating an issue is as easy as anything else; everything happens automatically and online, ensuring important communications are saved and Maintenance and Operations teams work in unison.