Defect handling

Register and solve defects quicker than ever

Allow operators to register defects on a handheld device. Assign tasks remotely, even across shifts. Register all performed work and communication on a shared system.

Paper procedures delay problem-solving…

In most factories, defects are registered on paper, whiteboards, or cumbersome software like Excel.

This takes up valuable time that could be used to work on solving the problem.

Additionally, analog tools make it difficult to keep track of all performed activities related to a defect, which causes extra difficulty when a defect has to be passed to a subsequent shift.

Luckily, connected worker tech has arrived to replace these headaches with practical automations.

…digital tech achieves a quick fix

4Industry’s dedicated defect-handling software deals with these problems by automating large swathes of the defect-handling process.

Instead of having to leave the shop floor to register a defect, operators can now use a handheld device to register it on the spot.

All performed activities are recorded in the system, so that the next operator or supervisor who has to deal with the defect instantly has all necessary information.

Additional steps like escalating an issue or validating a fix are automatically assigned to appropriate personnel by the system.

Digital defect handling in action

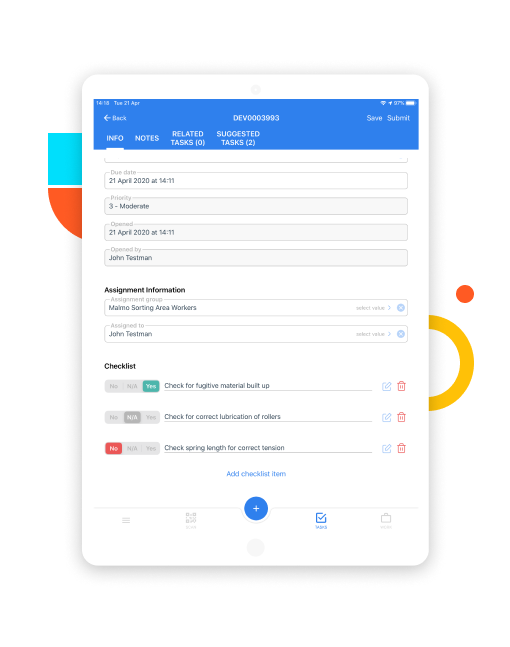

Defects are registered with a click by pressing the central button on 4Industry’s mobile app.

All necessary information can be filled in straight on the shop floor, after which it is processed and registered in a shared digital environment.

Operators can fix the defect on the spot or pass it on to a line leader, who can then assign it to more qualified personnel.

Operators can embed their defect report with pictures, videos, and written notes, which can be accessed by every subsequent person working on the defect.