5S

Create actionable, mandatory 5S audits

Ensure completion of 5S audits by assigning tasks, tracking progress, and recording results in a centralized digital environment.

Paper audits are promptly passed over…

Managing paper-based 5S audits can be difficult. Often, they are filled out without much care, which can negatively impact (food) safety and quality.

Moreover, when a problem arises, it is often not dealt with promptly and is instead overshadowed by more significant issues.

…going digital ensures completion.

4Industry’s dedicated 5S software ensures that audits are completed correctly every time.

Tasks can be remotely assigned to individuals and areas, and their completion can be monitored from a central digital location.

If an operator notices a problem during an audit, the software sends a notification to a safety or quality team. This ensures that the issue is not ignored and can be dealt with before it develops into a more significant risk.

Digital 5S in action

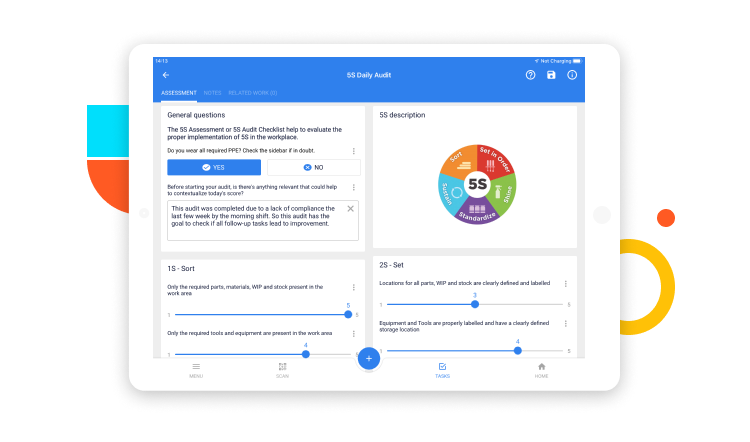

4Industry enables operators to execute 5S audits using a smartphone or tablet device.

All information relating to an audit, such as status, comments, and follow-up tasks, is stored in the system, ensuring traceability.

Operators report a hazard to Quality and Safety teams directly from the shop floor, turning the audit into an actionable hazard-prevention tool, rather than just a data-collection tool.

To provide problem-solving teams with accurate, up-to-date data to address an issue, the application supports taking pictures and videos.