An Overview of

TPM Manufacturing

Find out all about Total Productive Maintenance (TPM) and its 8 pillars, why and how to implement it in your factory, and the benefits of digitized TPM processes.

What is Total Productive Maintenance?

Total Productive Maintenance is a holistic approach to equipment maintenance that integrates maintenance activities with the manufacturing process. It seeks to reduce time and production waste, eliminate small stops and breakdowns, eradicate workplace accidents and achieve perfect production. As a lean manufacturing strategy and cornerstone of loss reduction, TPM manufacturing depends on your workers taking proactive measures to prevent downtime and environmental issues, as well as encourage a safe and healthy work environment—all while improving productivity.

What is TPM Manufacturing?

TPM manufacturing is the process of using factory equipment, personnel and supporting processes to maintain and improve production systems. TPM incorporates both proactive and preventative maintenance strategies to maximize equipment efficiency, with the ultimate goal of achieving perfect production.

It also engages everyone in the facility, from operators to engineers, so that they can participate in and contribute to the maintenance process, eliminating defects and increasing uptime.

Why Implement TPM in Your Factory?

Reduce waste and product defects

A goal of TPM is to keep machines running in their optimal condition. By properly maintaining equipment and proactively mitigating wear and breakdown risks, plant managers can reduce the amount of scrap and product defects that result from the process.

Reduce operating costs

Expanding on the previous point, TPM minimizes manufacturing scrap and product defects, reducing material costs. Maximizing uptime through proper equipment care also means you can ship goods quickly once they come off production lines, which lowers your inventory costs.

Increase productivity rates

By nature, less equipment breakdowns means your machines are running for longer periods of time, increasing your overall output.

Empower your workers

TPM calls for workers to actively step up and take care of their equipment—even before an issue arises. As a result, workers are accomplishing much more than just clocking into the factory each day. Rather, they’re taking greater ownership of their machines, which adds a valuable social aspect to their job function.

Minimize safety issues

TPM seeks to eliminate health and safety risks, leading to a safer workplace that has no adverse effects on workers’ physical or mental health.

Take a proactive approach to quality

TPM requires taking preventative, rather than just reactive, quality checks, ensuring all systems and processes are contributing to the production of high-quality products. Not only does this reduce the amount of product defects, but it can also minimize the amount of customer complaints.

The Goals of TPM

Based on the above reasons, we can say that the goal of TPM manufacturing is to eliminate the following plant issues in order to achieve a perfect production:

- Equipment breakdowns

- Small stops or slow-running machinery

- Product defects and scrap

- Safety and environmental issues

The eight TPM Pillars

Enable your operators and machines to achieve true world-class manufacturing with 4Industry, a mobile-enabled, highly customizable manufacturing platform.

Focused Improvement

All operators and technical personnel are encouraged to work together with the common goal of achieving regular improvements in equipment operation. These continuous improvement activities—also known as “kaizen” from a lean manufacturing perspective—go a long way toward identifying and resolving recurring production issues.

This pillar supports all the other TPM pillars, as it can help plant managers determine which aspect of their manufacturing operation needs improvement based on the company’s overall vision. For example, one company may want to reduce the number of safety incidents, while another may want to reduce its raw material cost per ton. Once a goal is identified, this pillar supports various plans of action that can maximize equipment efficiency and reduce operational losses.

These activities can include:

- Implementing root cause analyses (RCA) to eliminate breakdowns.

- Creating quality management matrices to identify quality issues.

- Instituting recurring kaizen-based meetings to manage teams and brainstorm solutions

Autonomous Maintenance

This pillar places the responsibility of routine maintenance practices—such as cleaning, inspection and lubrication (CIL) tasks—on machine operators. Doing so not only increases operators’ knowledge of equipment, but it also frees up engineers and other maintenance personnel for higher-level tasks. This pillar also improves early fault detection, empowering operators to identify and correct minor issues before they develop into long-term problems.

One helpful autonomous maintenance tool is the 5S model, which includes the following five steps:

- Sorting: eliminating items from a workspace that are not needed for current production.

- Setting in order: organizing the remaining items so that they are easily accessible.

- Shining: cleaning the work area daily, ensuring equipment runs correctly.

- Standardizing: creating procedures that reinforce the above three activities.

- Sustaining: regularly reinforcing the 5S standards via the work culture.

Quality Maintenance

Quality maintenance. Part of a company’s quality control practices, this pillar reinforces TPM’s goals of reducing product defects and lowering operating costs. Defect management processes like RCAs may be put into place, eliminating recurring or costly sources of quality defects. It’s important to note, quality maintenance is not just corrective. It’s also preventative, as quality managers can conduct various analyses to determine where in their factory things are going wrong and how to adequately address these issues.

Two helpful quality tools include:

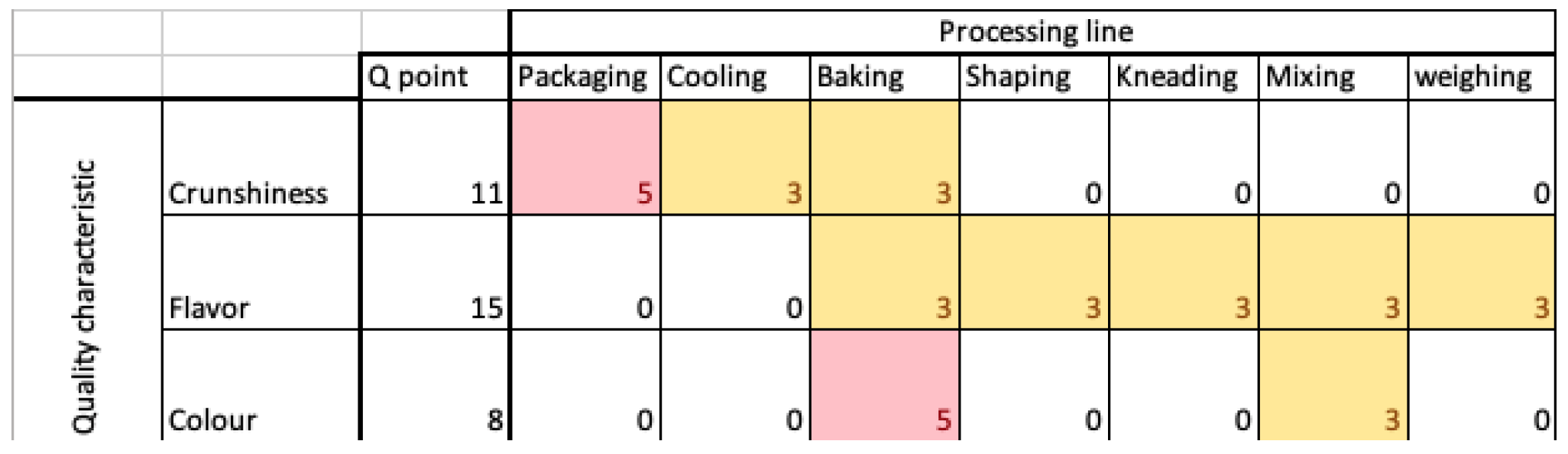

- Quality Assurance (QA) matrix: a table that enables managers to understand how current operating conditions may be contributing to product defects, as well as which processes and equipment are involved.

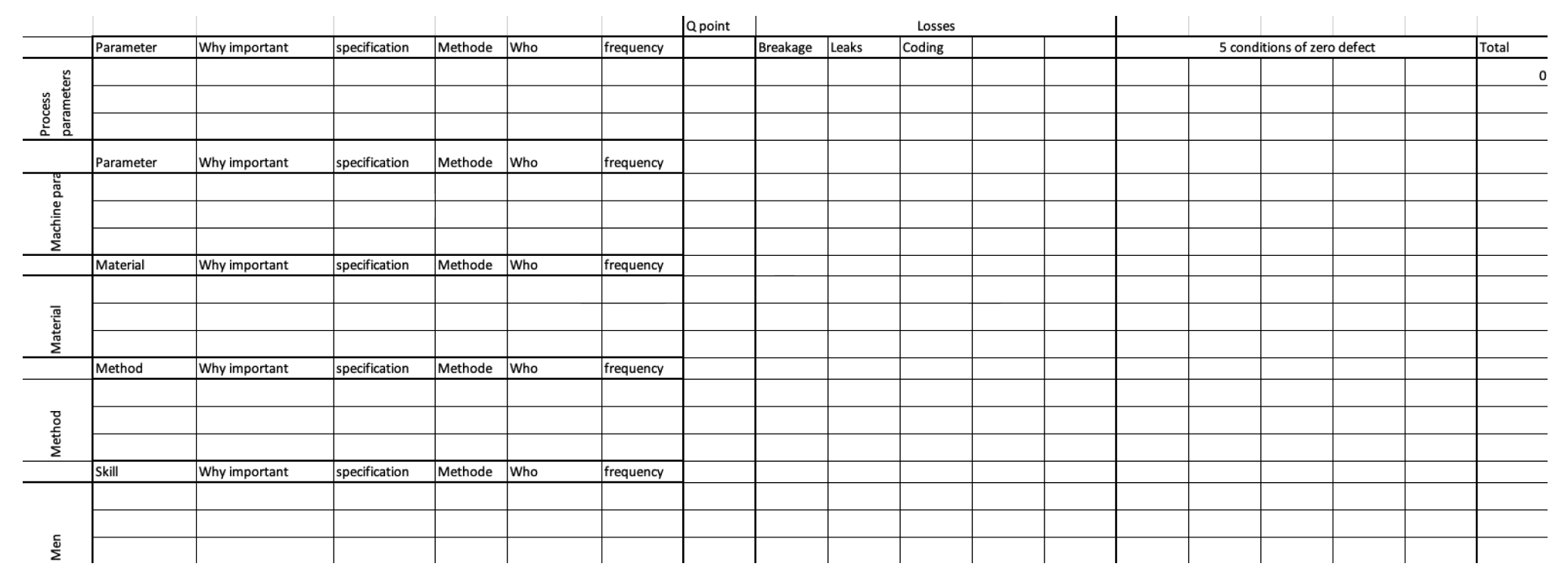

- Quality Maintenance (QM) matrix: a table that lets maintenance managers visualize all the machines, materials, personnel, methods and equipment parameters to ensure quality levels are maintained.

Planned Maintenance

To avoid equipment breakdowns and unplanned downtime, it’s important to schedule maintenance tasks. This pillar involves planning maintenance during those times when a piece of equipment is not slated for production, ensuring it has no effect on the current manufacturing process.

This pillar is closely related to the autonomous maintenance pillar, as it can improve how maintenance is being carried out on certain machines. The operators themselves can conduct minor maintenance measures on their own machines, for example, which frees up the scheduling of more complex maintenance tasks for technical personnel.

Early Management

This fifth pillar enables manufacturers to improve the design and implementation of new equipment based on the knowledge they gained through the other TPM pillars. The benefits of this pillar include reduced installation and startup times, as well as simpler maintenance.

This pillar typically falls into two categories. The first is early equipment management, which seeks to minimize losses with new or improved equipment. For example, a new machine may integrate easily removable or inexpensive parts, reducing maintenance costs compared to an older model. The second category is early product management, which involves modifying the product development process to ensure a product meets the customers’ needs. To use the French fry example from above, the food company may decide to go back to the drawing board and alter its recipe to achieve a crunchier texture.

Training & Education

The only way to ensure workers, operators and supervisors remain on the cutting edge of new equipment and technologies is to invest in their training and education. Operators with deeper maintenance skills can better identify emerging equipment issues, for example, while managers trained in TPM principles can better coach their employees.

This pillar enables plant managers to map out the current competencies within their factory. It also closes the gap between what they want and what already exists. Depending on the desired competencies, a plant manager may decide to invest in technical training, individual development or soft skills courses, for example. Having effective training processes in place also means any new employees will be onboarded quickly, enabling them to be productive much faster.

Safety, Health & Environment

The goal of this pillar is to maintain a safe and healthy work environment for all workers, free of health risks, accidents and near-misses. This pillar can be corrective or preventive in nature. For example, a safety officer can analyze what went wrong after the fact: “Someone slipped and fell because the floor was wet.” On the other hand, the officer can identify a potential issue and take the necessary steps to avoid a SHE issue from arising: “We need to mop up this wet spot on the floor before someone slips.”

In addition to workplace safety, this pillar also pertains to the operating environment’s effects on workers’ physical and mental health.

Managers and supervisors should ask themselves:

- How is the air quality in the plant?

- Is the factory at a suitable temperature?

- How are my workers’ mental states?

- Are workers being exposed to chemicals without proper protection?

- Is there anything in my workers’ workstations that could be considered unsafe?

Administrative TPM

Finally, this last pillar extends the benefits of TPM from the plant floor to the office, leading to improved administrative functions like order processing, logistics and scheduling. This pillar also engages administrative employees in the overall TPM process. At its heart, this pillar seeks to improve the various flows within a business, from planning to processing. Like the operations on the shop floor, these steps can be analyzed using various TPM techniques to reduce waste and costs.

The Implementation of TPM

If you’re new to TPM manufacturing, you can begin to implement a strategy in five easy steps. First, identify a pilot area for your TPM efforts.

You can select your target equipment based on:

- Which machines would be the easiest to improve

- Which equipment is the most problematic

- Where the current bottleneck is on your production line

Next, restore the equipment to its prime operating conditions using the autonomous maintenance steps. For example, workers should clean the area, remove unnecessary tools and begin to perform regular CIL tasks to identify and resolve any abnormalities. The next step is to track the overall equipment effectiveness (OEE) of your target equipment.

OEE, which is the percentage of planned production time that is truly productive, is a helpful metric to measure the success of your TPM strategy. According to Vorne Industries Inc, these percentages include the following:

The most effective way to track your revenues

source: Vorne Industries Inc

OEE, which is the percentage of planned production time that is truly productive, is a helpful metric to measure the success of your TPM strategy.

According to Vorne Industries Inc, these percentages include the following:

- 100 percent, which represents perfect production

- 85 percent, indicating world-class performance

- 60 percent, which, although common, leaves room for significant improvement

- 40 percent, which can usually be improved quickly by examining the three loss factors: availability, performance and quality

As part of this step, be sure to record and categorize all unplanned stops or breakdowns for at least two weeks. Once you understand where your biggest losses are coming from, the next step is to address and reduce these losses, utilizing the Focused Improvement pillar. And finally, your last step is to implement a planned maintenance strategy for all wear- and failure-prone components, minimizing the risk of future breakdowns.

The Benefits of Digital TPM

While you may already be implementing these or other TPM methods in your plant, chances are they still take the form of paper-based, manual processes. Improving TPM, as well as your overall operation, requires greater visibility into invisible or siloed production processes. The solution is to digitize TPM using a connected worker platform. These automated workflow-based tools offer user-friendly TPM-based modules to help you:

- Better manage deviations and maintenance

- Identify and quickly implement countermeasures

- Perform RCA and other analysis management processes

- Prioritize continuous improvement activities

- Assess and track quality and cleanliness using dashboards

- Access knowledge from anywhere on the shop floor using a mobile interface

These digital tools can also help you optimize inspections, audits and checklists that support your TPM strategy. For example, connected worker platforms with Smart Form integration allow you to customize digital forms for 5S audits, providing your TPM specialists with interactive, paperless tools that they can access from any mobile device. Best of all, these platforms digitally capture knowledge, creating an expansive, real-time knowledge base that encompasses your employees’ skills and expertise, as well as standardized procedures, safety measures, equipment manuals, RCA data and much more.

Continuously Improving TPM with Digital Tools

Digital tools make it easy to register feedback and trigger automated workflows from anywhere in the factory, enabling plant managers and supervisors to implement continuous improvement strategies quickly and efficiently. That being said, if you want to improve an aspect of your operation, you first need to know what’s currently going on. Connected worker software can help you visualize deviations, assigned tasks, RCA data, SHE issues and other information via dashboards and floor maps, enabling you to quickly identify where there may be room for improvement.

And if you’re new to TPM entirely, it’s more important that you start now versus asking where you should start. Whether you have extensive digital tools in place or not, a good first step is to identify the biggest source of loss or downtime in your plant—whether that source is a machine that breaks down frequently, or it’s a recurring safety issue. Once you’ve identified your continuous improvement issue, start with the data you already have and then begin to collect more.

Keep in mind, digital tools will make these processes easier and more actionable, enabling you to more effectively quantify the incoming data. Many connected worker platforms can even connect with external data sources, enabling you to transfer any relevant data into the app. With this solution, you can display data from your external sources as dashboards, achieving new insights and driving new action within the application.

Ready to get started?

Whether you’re new to TPM, or you’re a TPM veteran ready to take your strategy to the next level, the benefits of digitizing this manufacturing strategy are clear.

Not only does a connected worker platform fully engage all personnel in the TPM manufacturing process, but it also centralizes and updates plant-wide knowledge in real-time—providing you with the visibility you need to keep machines running smoothly.

Related Articles

Knowledge Management on the factory floor

Work on tasks from an easy-to-use Task Management system