The 16 Major Losses in Total Productive Maintenance (TPM)

Discover everything you need to know about the 16 major losses in Total Productive Maintenance (TPM).

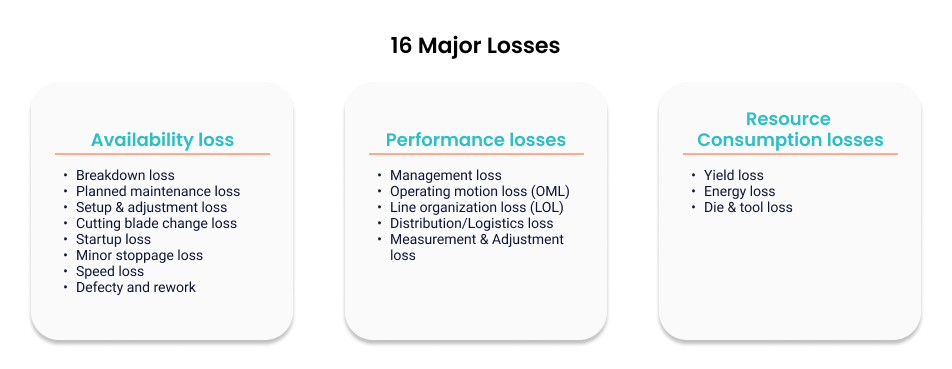

What are the 16 Major Losses in TPM?

The 16 Major Losses are a set of categories in Total Productive Maintenance (TPM) that encompasses all types of waste in a production system. In manufacturing, these categories help identify, classify, and ultimately eliminate wasteful practices.

All Losses are divided into three groups: Availability Losses, Performance Losses, and Resource Consumption Losses.

The exact names for the 16 Major Losses—and their subgroups—differ across instances.

In this article we’ll walk you through all 16 Major Losses in TPM, giving you a short description of each category along the way.

Availability Losses

The first group of losses is expressed in time and relates to the availability of machines. These losses play a big part in lowering a plant’s overall equipment effectiveness (OEE).

1. Breakdown loss

Breakdown or failure loss occurs when a machine

- fails and is unable to be operated

- runs at a lower-than-normal rate

- runs with occasional stoppages

- needs a part replacement to function properly

- needs repairs that last for more than five or ten minutes

There is a common misconception that it’s impossible to attain zero failures; failures are definitely not unavoidable.

With the right mindset and strategy, zero failures can be achieved.

Best practices here are to involve production personnel in the maintenance process, focus more on failure analysis, and upgrade maintenance systems.

2. Planned maintenance loss

When equipment is deliberately shut down for a (legal) inspection or maintenance, this falls under planned maintenance or shutdown loss.

Although necessary, this type of loss still affects the availability of machines, and it should therefore take as short a time as possible.

3. Setup & adjustment loss

This loss relates to changeovers, either between tools or the production of different articles. Setup loss is the time it takes between using/producing the old and new tool or article.

Adjustment loss, in turn, is the time it takes to tweak the machine until it’s executing its new function properly.

Single minute exchange of dies (SMED) can be used to keep this loss to a minimum.

4. Cutting blade change loss

The time it takes to replace a worn-out, broken, or ineffective cutting tool. This loss can e.g. be improved by investing in more durable blades.

5. Startup loss

Similar to adjustment loss, startup loss occurs when bringing a piece of equipment into an optimal operating state after a shutdown.

6. Minor stoppage loss

Minor stoppages can last from only a few seconds to several minutes. This loss is persistent and regular, and oftentimes difficult to detect.

There can be different causes for this loss: defective sensors, maladjusted machine settings, compressed materials, and so on.

A best practice to reduce this loss is to install equipment that’s capable of detecting and registering small stoppages.

7. Speed loss

Speed loss expresses the lost time that’s incurred due to a machine running slower than its standard speed.

Speed loss can also be applied to cases where a machine is running at a slower speed than industry standards.

8. Defect and rework

When a machine is producing articles of sub-optimal quality that require time to be fixed, defect and rework loss occurs.

Occasional defects are not the big issue here, as those are often easily fixed; the problem comes with chronic defects, as the cause of these is both hard to detect and hard to fix.

Performance Losses

This group of losses is expressed in both time and money, and primarily relates to losses that are related to the human workforce.

9. Management loss

Inadequate management can be a significant cause of production halting, e.g. due to there being insufficient spare parts, operators, or tools.

10. Operating motion loss (OML)

OML losses originate out of pointless or superfluous operator movement, often caused by a sub-optimal layout of the shop floor.

Spaghetti diagrams are sometimes used to get perspective on this type of loss.

11. Line organization loss (LOL)

Line organization loss occurs when the speed of the different steps on a line is unbalanced, causing certain operators to be idle.

This is not necessarily an equipment-related fault, as there’s also a human factor here.

Either a bottleneck analysis or a line balancing analysis can be very effective in bringing about a balanced, steadily flowing line.

12. Distribution / Logistics loss

This loss applies to everything related to the delivery of products to a factory (e.g. raw materials). The unloading of products is a point where this loss can occur.

Although automation can lead to a reduction in unloading time, unloading is mostly still done by humans.

13. Measurement & Adjustment loss

If the quality of products is consistently sub-optimal and the root cause can’t be found, the consequence is often an excessive number of adjustments to machine settings (so as to keep product quality consistent).

This constant inspecting and adjusting can lead to a significant waste of time.

Resource Consumption Losses

Resource consumption losses—expressed in money—occur when energy, materials, or parts are used in an ineffective manner.

14. Yield loss

Yield loss expresses the loss that occurs when a part of the total production output has to be discarded because of defects.

15. Energy loss

Energy loss encompasses waste due to the direct material loss of energy (e.g. leakage of oil) and its inefficient use.

Energy already forms a big part of manufacturing costs, so reducing energy loss as much as possible is a high priority for manufacturers.

16. Die & tool loss

The last of the 16 Major Losses in TPM applies to the cost of the items needed for jig and die repairs, tool replacements, machine restorations, and so on.

Want to stay up to date with everything related to modern manufacturing? Connect with us on LinkedIn to find out about our latest blogs, whitepapers, reports and much more!

Related Articles

Knowledge Management on the factory floor

Work on tasks from an easy-to-use Task Management system