A Short Guide to

5S in Manufacturing

Find all you need to know about 5S in manufacturing, and discover how digital tools can help you enhance 5S in your factories.

What is 5S in Manufacturing?

The 5S methodology is a cyclical, 5-step technique that is used in manufacturing to create workspace that enable workers to perform their work in a efficient, effective, and safe way.

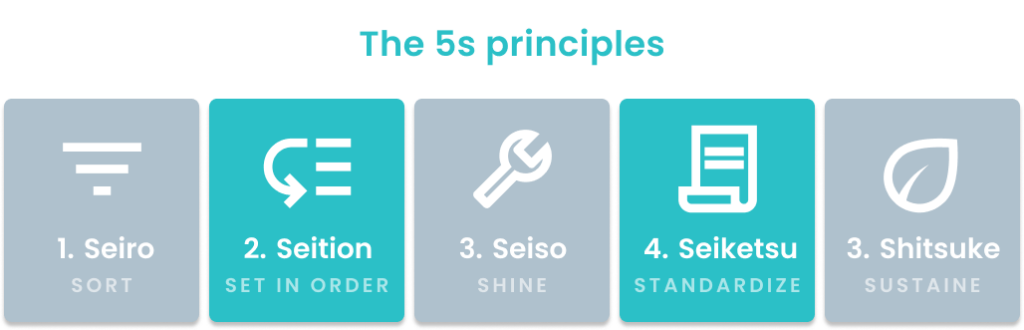

Like many of the core concepts of Lean manufacturing, the 5S method originates in Japan. The name “5S” comes from the Japanese words for each of its five pillars:

- Seiri (sort)

- Seiton (set in order)

- Seiso (shine)

- Seiketsu (standardize)

- Shitsuke (sustain)

What are the 5S pillars?

You may think 5S is just about sparkling surfaces and neatly-mopped floors, but its effect actually reach far further than that.

A well-run 5S program can improve things such as safety, efficiency, and even equipment uptime.

It’s because of these reasons that 5S is considered to be an essential part of Total Productive Maintenance (TPM), the Toyota Production System (TPS), Lean/Kaizen manufacturing, and continuous improvement.

Let’s quickly explore the purpose of each of the 5S pillars.

1. Seiri (sort)

This first step is about eliminating any item that does not need to be present on a workspace. In other words, clutter is replaced by clarity.

Benefits

- More organized workspace

- Increased efficiency

- Decreased chance of making a mistake

2. Seiton (set in order)

After all unnecessary things are removed, the remaining items can be ordered in a fixed place to make them easily accessible and easy to find.

Visual Management tools like tags and colors can be helpful in achieving this. Items and tools should be in close proximity to the place they are used, which key in reducing waste (muda).

Benefits

- Designates a place for each item

- Less time wasted on finding tools

3. Seiso (shine)

Tools, machinery, and workspaces should be cleaned, inspected, and undergo maintenance in order to prevent:

- Unsafe situations (it is e.g. much easier to spot a fluid spill in a clean environment)

- Health hazards (for both employees and end-users)

- Equipment breakdowns, errors, and deviations

4. Seiketsu (standardize)

Standardization turns an isolated 5S-event in something that is fixed, repeatable, and scalable. To standardize means to gather the best practices discovered in the previous steps and turn them into a set of concrete instructions for your workers.

Benefits

- Maintains improvements done in first three steps

- Ensures work is done identically in the entire factory

- Facilitates sustainability of 5S (see next step)

5. Shitsuke (sustain)

This last step is key to guaranteeing the continued success of any 5S program. Now that you’ve standardized your 5S program, its time to flesh it out into regularly ocurring tasks for frontline workers.

In other words: sustain prevents people from slipping back into old habits. This step involves defining the work that needs to be done,setting up schedules, assigning tasks. Furthermore, standardization must ensure a consistency across workers, shifts, and even throughout the entire factory.

Benefits

- Guarantees continued success of 5S

- Prevents slipping back into bad habits

- Creates a fixed set regularly ocurring tasks

How do digital tools enhance 5S?

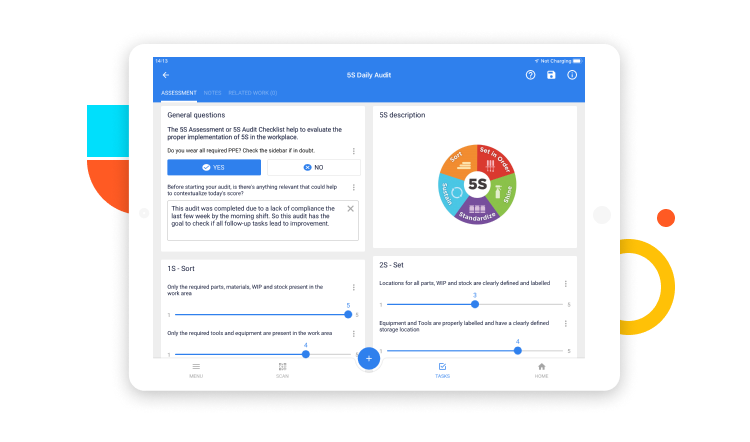

A Connected Worker Platform like 4Industry can be a big help in guaranteeing the continued success of 5S programs.

Its benefits come mostly in step 4 (standardize) and 5 (sustain) of the 5S methodology.

4Industry enables you to create standardized, digital 5S audits that are completed by operators on a smartphone or tablet device. This gets rid of all the impracticalities of paper and prevents operators from using outdated 5S audit sheets.

5S audits can be scheduled and assigned to operators ahead of time, while their completion can be easily tracked on any desktop computer.

If operators notice an issue, it can be escalated to Safety and Quality teams in a second, preventing it from turning into a much more significant problem.

If you’re interested in getting started with digital 5S, you can read read more about 4Industry’s 5S software here. Or if you’d rather schedule a demo, that’s also a possibility—click here!

Related Articles

All You Need to Know About Heijunka in Manufacturing

Manufacturing Cycle Time Explained (+ Tips on How to Improve)