Everything You Need to Know About

Continuous Improvement

Learn what Continuous Improvement (CI) is, how to implement it, and what the benefits of digitized CI are for your manufacturing organization.

What is Continuous Improvement?

Continuous improvement (CI) refers to the ongoing effort to enhance processes, goods or services either through small, incremental steps over time or through “breakthrough” developments that may happen all at once. Its foundation includes implementing new opportunities for improvement, measuring the impact of these activities and then sharing the knowledge. Over time, this cycle becomes more self-sustaining within an organization, generating greater enthusiasm and engagement among all the stakeholders.

The backbone of any successful manufacturing operation, continuous improvement in this context means searching for and resolving defects, deviations and other bottlenecks within a plant in order to improve production processes. It can incorporate a variety of strategies, from total predictive maintenance to lean manufacturing. It can also employ one or many data-driven models to guide improvement practices.

Continuous Improvement Models

There are several CI models that organizations can use to drive toward identifying and making sustainable changes. One tried-and-true example is the Deming cycle, which is also known as the “Plan, Do, Check and Act” (PDCA) cycle. It includes the following steps:

Plan, Do, Check, and Act (PDCA)

There are many reasons why the PDCA model is effective. For one, it is a practical, step-by-step and systematic approach that uses evidence in the form of data to guide change. It is also continuous in that it delivers improvements over several steps, rather than in one giant leap. And finally, the cycle itself is flexible; implementers can easily make course corrections based on the observable changes, and they can bring in other CI tools or methodologies depending on their specific needs.

Plan – Identify opportunities for improvement and create a plan of action.

Do – Implement the plan on a small scale.

Check – Measure changes using data to determine if the plan was effective.

Act – Based on the data, either implement the change on a larger scale or cycle back to a previous step if the desired results were not achieved.

In addition to the PDCA cycle, there are several other CI approaches, many of which were inspired by this model. Some examples include:

Lean Manufacturing

Continuous improvement is an important part of lean manufacturing, which is founded on the idea of Kaizen (see below). Under this strategy, which was originally developed by Toyota after World War II, manufacturers should focus on building to order, rather than building to sales or production targets to avoid overproduction. According to the lean manufacturing model, each process should produce only what is needed by the next process in a continuous flow. It also seeks to eliminate the following sources of waste, or non-value-adding tasks:

Muda

The seven process wastes, or non-value added tasks, pertaining to transport

Mura

Waste created by inconsistent workloads

Muri

Waste created by overburdening equipment or operators

Six Sigma

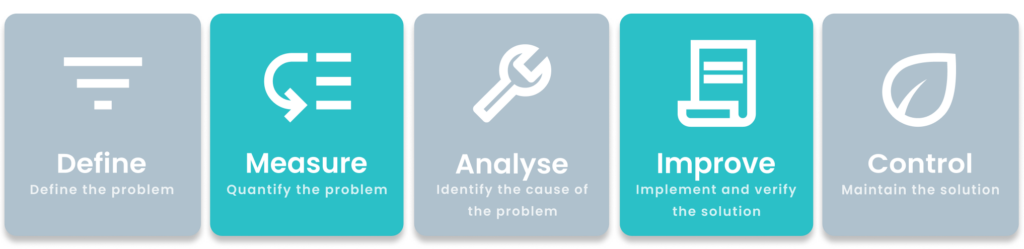

A model that uses statistical analysis to make process improvements. The name itself, Six Sigma, is taken from statistics, in which one sigma represents one standard deviation away from the mean on a normal distribution. The goal of this model, as the name implies, is to eliminate defects while driving toward six standard deviations between the mean and the nearest limit in any process. In terms of putting this model into practice, Six Sigma’s toolkit includes the DMAIC, or “Define, Measure, Analyze, Improve and Control” process, for improving existing processes. It also includes the DMADV, or “Define, Measure, Analyze, Design and Verify” process, for developing new products.

The Theory of Constraints (TOC)

A scientific approach to CI that seeks to identify what stands in the way of achieving a goal and then making systematic changes until that constraint is eliminated. TOC tools include:

- The Five Focusing Steps for identifying important constraints. These steps include:

- Identifying the bottleneck (“identify”);

- Making quick improvements using current resources (“exploit”);

- Reviewing all other processes to ensure they support the goal (“subordinate”);

- Consider if any further actions must be taken (“elevate”); and

- Addressing the next bottleneck in the operation (“repeat”).

- The Thinking Process for analyzing these issues. Ask the following questions: What needs to be changed? What should the issue be changed to? What activities will bring about the change?

- Throughput Accounting, which uses the following metrics to measure performance: throughput, investment and operating expenses.

Total Quality Management (TQM)

Total Quality Management (TQM): A data-driven model that focuses on improving internal processes to deliver goods and services that meet or exceed customer requirements. Under this model, all stakeholders within an organization participate in the improvement process to achieve customer satisfaction.

3 guiding principles for Continuous Improvement implementation

There are 3 guiding principles of continuous improvement that are useful for any manufacturer who is new to its implementation.

Lasting change doesn’t depend on large-scale events

First and foremost, lasting change doesn’t depend on large-scale events or paradigm shifts. Rather, effective CI often involves taking small, incremental steps that are much more practical and inexpensive to implement.

Employees are indispensable to the CI process

A second guiding principle is the idea that employees are indispensable to the CI process. Engaging staff members in continuous improvement not only taps into their own personal knowledge base, but it also empowers them to take charge of and put their ideas into practice. Encouraging feedback and keeping communication lines open are key to the success of this process.

Any improvements should be measurable

And finally, any improvements should be measurable, enabling an organization to review, repeat and apply the process to other aspects of the operation.

Continuous Improvement Activities

In addition to these 3 principles, there are many continuous improvement activities that a company can perform — regardless of its operational philosophy, business strategy or CI model, whether Six Sigma, TQM or some other approach. These CI activities include the following:

Kaizen

Stemming from two Japanese words — “Kai” meaning “improvement” and “Zen” meaning “good” — Kaizen translates to “continuous improvement” and is applicable to many areas of life, including professional and personal development. As the basis of the lean manufacturing strategy, it seeks to remove as much waste as possible from production processes, improve product quality and increase profits.

Kaizen seeks to engage all workers in a company’s continuous improvement process, encouraging them to look for, suggest and implement new ideas that can improve some aspect of the factory floor. As a step-by-step plan of action, it includes the organization of workshops dedicated to identifying, implementing and following up on areas of improvement within the company. Typically, these meetings involve the following steps, which can become more involved with larger or more complex problems:

- Identifying problems

- Verifying team members

- Understanding the current process

- Analyzing the problem

- Creating the solution

- Testing the solution

- Measuring the results

- Standardizing the solution

Root Cause Analysis and the 5 WHY Methodology

Root cause analysis (RCA) is a systematic approach to deviation management that empowers users to find and eliminate the root cause of an issue, event or deviation to ensure it doesn’t happen again. In terms of its benefits, RCA enables organizations to:

- Identify the root cause of a problem to avoid simply treating the symptom.

- Develop a systematic approach to problem solving.

- Identify current and future areas for improvement.

- Establish repeatable, measurable and step-by-step processes.

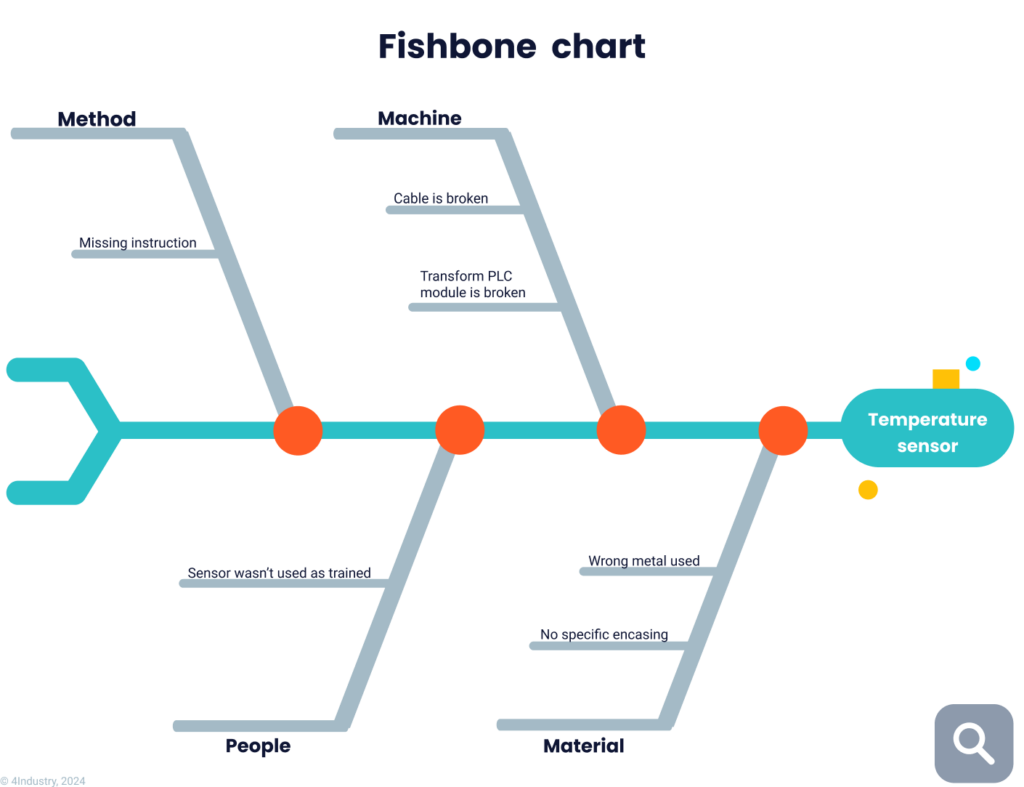

Plant managers can perform an RCA using multiple processes like the 5 WHY methodology. One of the most effective tools in the RCA arsenal, this interrogative technique consists of asking “why” five or more times regarding an issue in order to identify cause and effect. Each answer forms the basis of subsequent “why” questions, bringing the implementer closer to the root cause of the issue. In addition to 5 WHY, other common RCA methods include the fishbone diagram, also called the Ishikawa diagram , which visually depicts the effects of an issue, as well as the various causes that contributed to those effects. Another is fault tree analysis — a deductive, top-down illustration that depicts the various causes that contribute to an event.

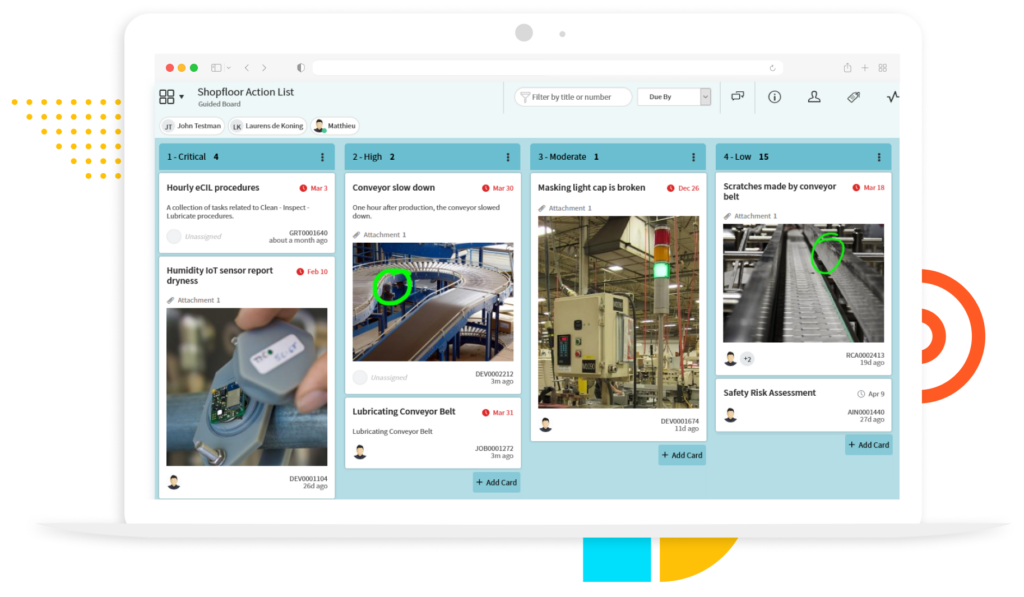

Kanban

This lean manufacturing technique takes the form of a board that visualizes all works in progress to provide participants with a view of the tasks’ progress from start to finish. This tool, which was developed by Toyota as part of its lean manufacturing strategy, provides a way to visualize and manage workflows, eliminate interruptions, create feedback loops and improve collaboration among workers through greater process visibility. In addition, Kanban boards can help organizations improve task visibility and transparency. Some of the information can include:

- The number of tasks a department or team can deliver in a given period of time.

- A way to avoid overburdening workers (Muri)

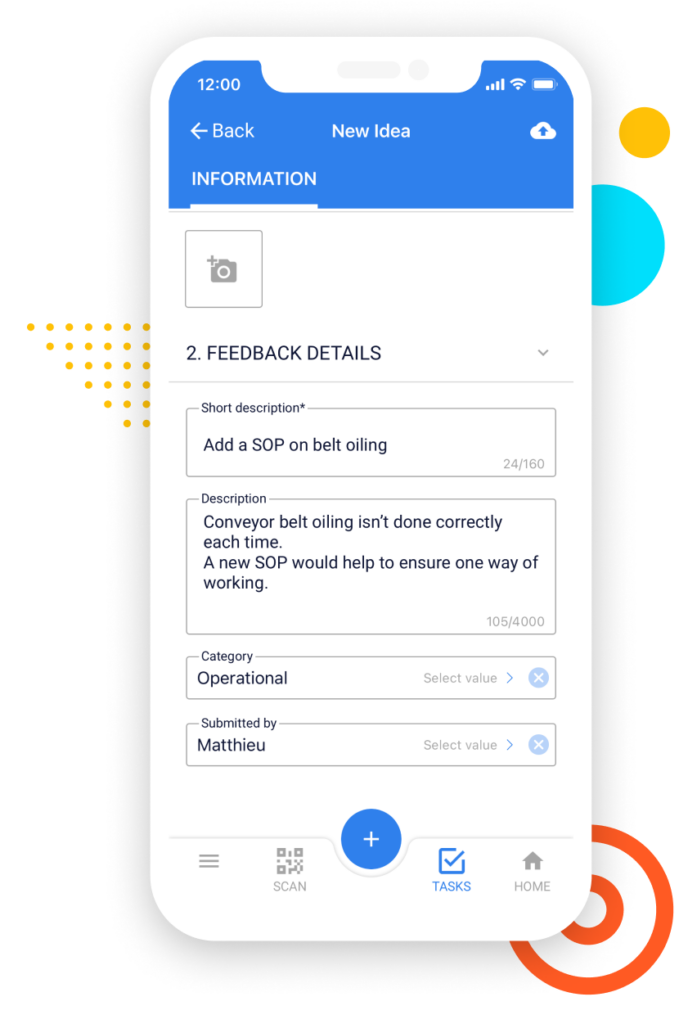

New Idea and Feedback Management

In order to improve, it’s important for companies to share and manage their information and knowledge, as well as encourage the creation of new ideas. One way to achieve these goals is to tap into your workers, as they — more than anyone — know where improvements can be made within the organization.

Regular brainstorming sessions, polls, surveys and suggestion boxes are some of the traditional methods for collecting and receiving feedback on new ideas. On the other hand, digital tools, which are accessible from smart devices, make it easy for any stakeholder to register new ideas or provide feedback on an existing process. These tools still tap into workers’ unique skillsets and knowledge, but they remove the friction that comes with submitting, managing and fast-tracking CI solutions.

The Benefits of Digital Continuous Improvement

Although the continuous improvement process is nothing new, it has, until now, mostly taken the form of manual processes — from streams of paper tacked to bulletin boards, to outdated Excel spreadsheets that are easily lost or deleted. That being said, it can be difficult to unlock all the potential CI holds for your organization using these limited processes. On the other hand, rolling them up into an interactive, easily accessible connected worker platform can take your CI efforts to the next level. As a result, you can more effectively define and monitor your operations, manage deviations, streamline the creation of new ideas and much more.

Register and manage deviations quickly and effectively

If a breakdown occurs, deviation management modules let you easily manage the issue. After registering a deviation, these digital tools propose countermeasures based on historical data and a centralized knowledge base. Some tools even leverage machine learning models to learn from past deviations and suggest the most appropriate actions.

Once a deviation is registered, you can then create an RCA directly from the record. Connected worker platforms take the traditional benefits of the RCA process further by storing information as interactive knowledge articles. They also let you streamline and manage RCA-related job tasks and trigger maintenance requests.

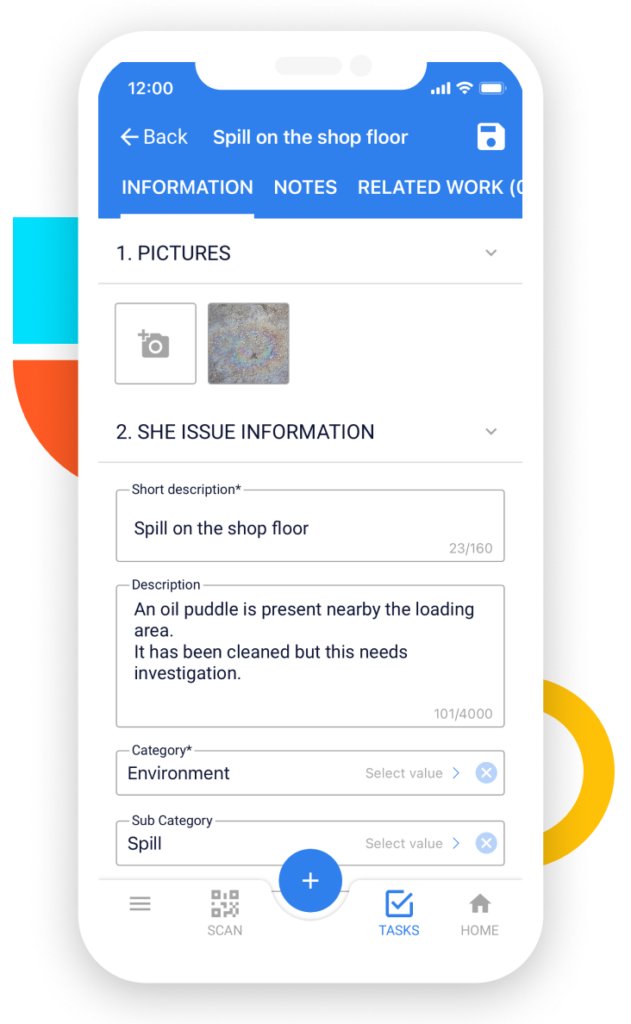

Enhance safety, health and environmental (SHE) measures

Connected worker platforms allow you to easily improve SHE procedures using several real-time features. For example:

- Receive alerts when an observation or incident is created within the app.

- Capture data from audits like hazard and operability (HAZOP) studies.

- Easily store the latest, up-to-date information for future use.

Automatically measure task duration and execution

Digital platforms automatically track how long it takes workers to complete a task or implement a standard operating procedure (SOP). Linked to a task executor module, this feature enables you to see which step or team is causing any bottlenecks. You can also precisely measure the status of each task to see if things are moving fast enough. By providing this much-needed visibility into the task execution process, connected worker platforms make it easy to identify where a process can be improved to complete the job faster.

Visualize works in progress, CI tasks, metrics, and more

Many digital platforms feature tools that visualize lean manufacturing techniques and other CI tools. For example, interactive digital Kanban boards come with a drag-and-drop feature, enabling you to prioritize and assign tasks to workers, manage works in progress and report on progress. Many digital platforms also utilize dashboards that display key performance indicators (KPIs) and other production metrics in interactive, meaningful ways. Thanks to this capability, you can more easily identify areas for improvement and enhance the speed, efficiency and uptime of their operation.

Manage and share updated knowledge articles

Unfortunately, it’s not enough to simply translate SOPs, technical manuals and other knowledge articles into digital documents like Excel spreadsheets or PDFs stored in network drives or SharePoint. Rather, this information becomes most impactful when it is intuitive, interactive and searchable. Improving the global knowledge management process, which is key for implementing and improving CI, connected worker platforms let you capture and share collective, plant-wide knowledge with multi-language and automatic translation features. And best of all, there is never any doubt if the knowledge articles within the application are the most up-to-date versions or not. Having this kind of comprehensive, interactive knowledge base in place enables you to overcome the communication challenges that arise between shifts. It also transcends shifts entirely, expanding to include all lines in a factory and all factories around the world.

Get Started Today

There are many benefits that come with digitizing continuous improvement. Not only do connected worker platforms engage all stakeholders in the CI process, but they provide a suite of interactive tools that enable you to more effectively visualize data, share knowledge articles and manage deviations. Together, these benefits can help you identify and implement new opportunities for change, measure the impact of these activities and share what you’ve learned as you drive toward further improvement.

Related Articles

Knowledge Management on the factory floor

Work on tasks from an easy-to-use Task Management system